How the development, validation, and large-scale deployment of online solids management systems is saving operators money by releasing flowback equipment sooner, minimizing equipment damage due to solids carry-over, and reducing the need for shutdowns and confined space entry cleanout operations.

Pounding Sand

Oil and gas wells seldom produce a nice clean stream of hydrocarbons. A horizontal separator is typically the first piece of equipment downstream of the wellhead choke, dividing the flow into gas, oil, and water streams based on density difference.

Each stream may be further refined to optimize gas and oil quality for export, and to minimize the hydrocarbon content of produced water. Gas compressors and liquid pumps are used to move things around, and storage tanks hold inventory until it is trucked off site.

This proven equipment runs smoothly, requiring predictable maintenance, until a fourth phase comes along: solids.

In conventional reservoirs, produced solids originate from either unconsolidated formations (i.e., sand production) or precipitates coming out of solution as the wellbore pressure drops (e.g., paraffins, waxes, and asphaltenes.) The rate of solids production can be managed using downhole sand control (e.g., sand screens) and by chemical injection.

Across today’s dominant shale plays, however, most solids flowing into surface production equipment are back-produced proppant from hydraulic fracture stimulation. This is an inevitable consequence of the stimulation process, which can only be partially mitigated (e.g., using resin-coated proppants.)

Flowback equipment installed temporarily between the wellhead and the first stage separator intercepts the highest levels of solids production as a new well cleans up. However, this is costly, and operators are keen to release the flowback spread as soon as possible. This can lead to significant solids accumulating in the separator after the flowback spread is released and, if not addressed there, making their way into downstream equipment.

The consequences of unmitigated solids accumulation and carry-over include reduced separation efficiency, suboptimal oil and water quality, damage to valves, pumps, and heater-treaters, and pipe erosion.

It is therefore essential to regularly remove solids from separation and process equipment to optimize performance, minimize maintenance costs, and mitigate the risk of leaks and environmental damage.

Solids Management the Hard Way

Traditional solids removal requires taking separators, vessels, and tanks out of service for depressurization, emptying, and cleaning.

Cleaning larger tanks and vessels requires removing a hatch and performing a confined space entry operation—sending a human inside to shovel, hose, and scrub out the solids. This is dangerous work, often requiring the use of a hazmat suit and breathing apparatus while working in a dark, hot, slippery environment. Sadly, serious accidents are not uncommon.

While smaller separators are often partially cleaned without physical entry, the operation still requires the vessel to be taken out of service and opened, exposing personnel to hazardous vapors that emanate from the open hatch.

Cleanout operations are also costly. In addition to service fees, the operator must account for production deferment during the cleanout and while ramping wells back up to full production.

Unsurprisingly, this drives operators to delay cleanouts for as long as possible, which leads to solids carryover from separators into downstream equipment whenever they overtop the vessel’s internal weir. Ensuing dump valve erosion can lead to oil (and even gas) being carried into the water leg, creating a hazard in, and unmitigated emissions from, the produced water tank battery. Other equipment, such as pumps and heater-treaters, may be damaged by solids incursion.

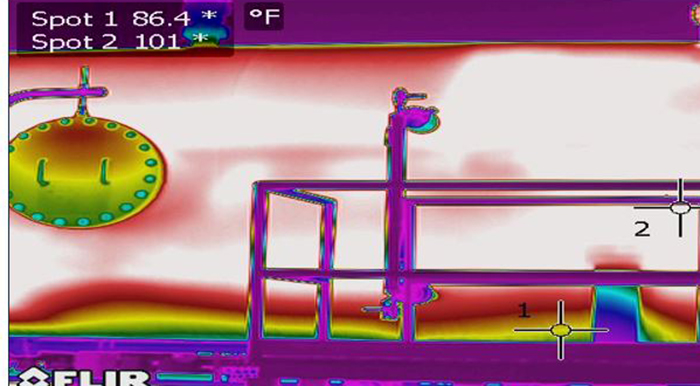

Measuring solids accumulation inside solid walled pressure vessels isn’t easy, either. Infra-red imaging

can be used to estimate the height of solids inside the vessel (see Figure A) but is an inexact measurement and requires regular site visits by a skilled technician.

Furthermore, solids production from a given well or pad can be highly erratic, causing a sudden increase in solids accumulation that may go undetected between period infra-red measurements.

Solids Management the Online Way

For several decades, the operators of large storage tanks, such as those found at refineries, have installed permanent cleaning systems to remove solids without having to take tanks out of service. However, such systems are too costly for deployment in onshore field equipment.

Systems using water jets to stir up sand for removal via drain nozzles have been tried but were found to be relatively ineffective and prone to eroding the vessel wall.

The breakthrough came when fit-for-purpose materials were combined with vortex fluidizing technology to produce an affordable, effective online approach to solids removal.

The breakthrough came when fit-for-purpose materials were combined with vortex fluidizing technology to produce an affordable, effective online approach to solids removal.

The system is constructed from high-density polyethylene (HDPE) components, which are suitable for operation in the relatively low pressures and moderate temperatures found in most onshore applications. HDPE pipework is also flexible, making the equipment highly adaptable to different vessel sizes and internal configurations.

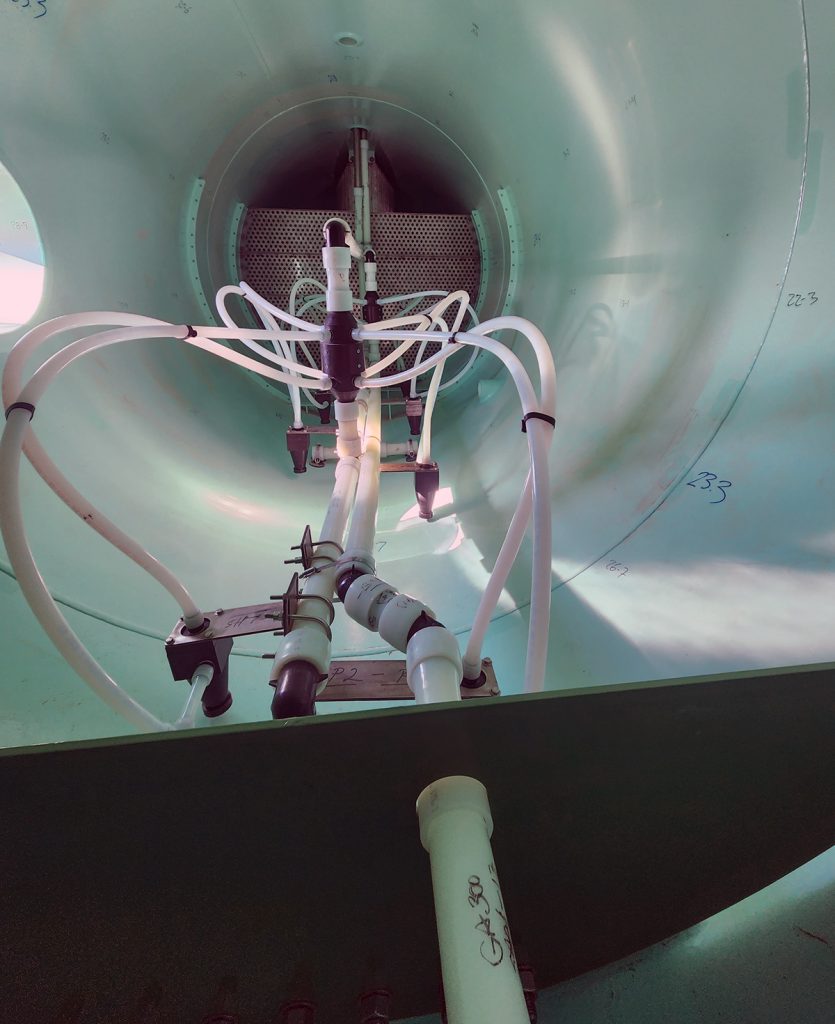

Water is pumped into the system through an available nozzle and via distribution hubs to vortex fluidizing units (VFUs) arranged along the bottom of the vessel (see Figure B). The VFUs swirl surrounding solids into a slurry, which is then sucked out of the vessel via a discharge line to a waiting vacuum truck or storage tank.

The true beauty of this approach is that it can be activated while the vessel remains in service, avoiding production deferment and obviating the need for human intervention.

While permanent pipework and pumping equipment are typically installed to support the regular cleanout of central production vessels, trailer mounted equipment and temporary pipework can be used to periodically activate the system in a well pad separator or tank, using a water truck and vacuum truck as shown in Figure C.

Anatomy of an Octopus

The online solids management system is known as the Octopus™ because each distribution hub typically connects to four fluidizing units, each with a clean water hose and a slurry return hose (so, eight “legs” in total).

Installation can be performed during the fabrication of a new vessel or during a shutdown (and cleanout) of an existing vessel.

Multiple Octopi are installed in larger vessels and tanks to ensure effective solids removal from critical areas such as near the inlet of a separator, or near the inlets and outlets in a larger tank.

Octopi in the Wild

At the time of writing, over 150 Octopus units have been deployed across the Permian Basin. Separators ranging from 60” to 120” in diameter and tanks of many sizes have been fitted with the system for both independent and integrated operators, and at water midstream facilities.

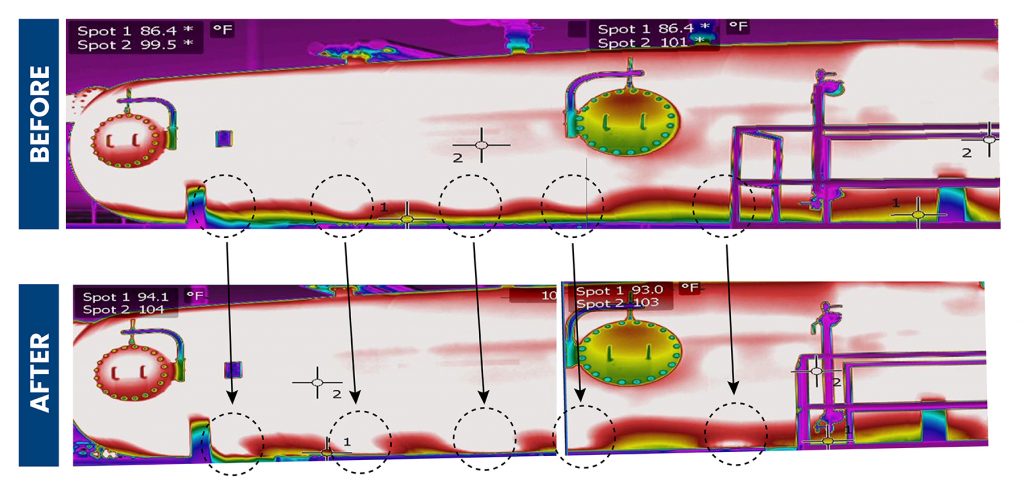

Initial deployments aimed at verifying the system’s ability to effectively clean the vessel were deemed highly successful, based on before and after IR imaging (see Figure D).

For each cleanout operation, the service cost is reduced by more than two thirds and production deferment is avoided entirely. This usually pays for the Octopus hardware and installation with the first cleanout cycle.

More recent deployments have multiplied the return on investment by giving the operator confidence to release post-frac flowback equipment sooner than normal. Rather than keeping a sand knockout unit on site for several weeks, until sand production levels fall below a stringent threshold, they can release the unit much sooner and handle the remaining solids in the first-stage separator.

While flowback spread rates vary greatly between contracts, we conservatively estimate a 3- to 4-week reduction in flowback time to be worth $80-120k—several multiples of the cost to install an Octopus™ system in most vessels.

At a time when oil prices are expected to remain “lower for longer,” these savings are a welcome sight for cost-sensitive operators.

The health, safety, and environmental benefits of eliminating traditional confined space entry cleanouts must also not be overlooked, as well as reduced maintenance and spill remediation costs thanks to more regular and more effective online cleanouts.

Imperfections and Limitations

The Octopus is as close to a “no-brainer” as you’re going to find for most onshore operations where solids production is a regular headache. However, as with any technology, we must acknowledge a few limitations and drawbacks.

Vessel size: The horizontal footprint of the vessel must be large enough to accommodate the online solids management system. Very small separators, such as those used on many gas wells, and some vertical vessels are not candidates for this technology.

Temperature: The standard system, manufactured predominantly from HDPE, is suitable for vessel working temperatures up to 160˚F (71˚C). For vessels operating at higher temperatures, components manufactured from stainless steel are available.

Retrofit Limitations: Most candidate vessels can be retrofit with online solids management systems by making use of existing drains and spare nozzles for water supply and solids-laden slurry removal. However, if such inlets are not available or are unsuitable, the cutting, welding, and certification of new vessel penetrations may be required.

Choke Wear: When a flowback spread is released before solids production has been minimized—as is the case when using an online solids management system to handle the remaining solids in the first stage separator—the wellhead choke and associated pipework are exposed to elevated solids and subject to increased wear. The cost of additional monitoring and maintenance in this area should be factored into the overall cost-benefit analysis but are generally low compared to the cost savings from early flowback spread release.

Conclusions and Industry Guidance

The back-production of solids from onshore wells, especially those completed with hydraulic fracture stimulation, is a persistent and costly challenge.

Flowback services deployed during the initial clean-up phase after a new well is turned in line are costly, and most wells will continue to produce solids after the flowback spread has been released.

Solids production is typically difficult to measure and intermittent in nature. Some vessels will therefore experience minimal solids accumulation over long periods in service, while others rapidly fill up with solids.

Excessive solids accumulation leads to reduced separation performance and solids carry-over into the water leg, damaging downstream valves, pipework, and equipment, and contributing to solids accumulation in storage tanks. This can cause out-of-spec product, equipment failure, spills, and fugitive emissions.

The vessel and tank cleanouts that must be performed to avoid these undesirable consequences are inherently costly (both in terms of service fees and deferred production) and hazardous to crew and the environment.

A superior solution has been developed using vortex fluidizing units that effectively remove solids while the vessel or tank remains in service. This avoids the need for process interruption and hazardous cleanout operations while greatly reducing the risk of downstream equipment damage due to solids carry-over.

Such systems are cost-effective, often paying for themselves within weeks by facilitating the early release of flowback equipment. Subsequent online cleanout operations are significantly cheaper than traditional cleanouts that required shutting down and draining the vessel or tank.

With more than 150 such systems in operation, online solids management is fast becoming the “standard of care” for production systems across the Permian Basin, with deployment in other liquids-producing onshore basins beginning to follow suit.

Operators are encouraged to evaluate online solids management for inclusion in their basis for design of new well pad and production facilities, as well as for retrofitting to existing vessels and tanks that are experiencing solids accumulation.

For more information on Wolf Process Technology, go to WolfProcess.com.