The move to laterals has the Permian Basin turning the bit in earnest, but not every driller is finished with the traditional vertical well.

When Jim Henry stood up at a networking meeting in Midland recently and commented that his company, Henry Resources, will start using some horizontal rigs, everyone knew the world had changed.

When Jim Henry stood up at a networking meeting in Midland recently and commented that his company, Henry Resources, will start using some horizontal rigs, everyone knew the world had changed.

Used to be in the land of drilling the vertical rig ruled supreme. No more. Henry’s comment reflected the fact that the horizontal rig is overtaking the vertical tool in certain oilfields. An increasing number of companies are opting for the higher technology (and higher costs) with hopes of pulling more crude oil (and more money) out of the ground.

“It’s a new stage; something we all have to learn,” Henry said afterward. “Most all Wolfberry drillers are learning to do horizontal.” And so the independent oilman who has tallied success after success in the Wolfberry is upgrading his company’s techniques.

“It’s the wave of the future,” he added.

That wave of change also translates into a lower rig count—since there are few horizontal rigs that confine their drilling to one square mile—and more “green” rigs as the industry seeks ways to spare the environment. The vertical rigs, though, won’t hit the junkyard just yet. There is still a demand for this niche drilling, as one San Angelo driller testified.

The switch from vertical to horizontal drilling in the Permian Basin was the topic of discussion at the recent Hart 2013 Oil Executive Conference in mid-October, with a panel of local experts agreeing that companies are moving to the newer technology.

Reports by Baker Hughes Incorporated indicate that the focus has officially switched to horizontal drilling. As of October 18, there were 228 horizontal rigs reported in the Permian Basin as opposed to 220 vertical. Jared Blong, CEO and president of Octane Energy in Midland, has been tracking the drilling rig and well starts for months as he initiates work on the first horizontal rig for his firm.

“This is a significant transition in the marketplace,” Blong said.

He offered some reasons why the Permian Basin has been slower to adopt the horizontal rig. “The Eagle Ford and the Bakken have been getting all the press,” he said. “But we’ve been drilling out here since 1921. The starting point for us was a lot different than those other basins.”

Henry noted that the Permian differs from other basins in that “it is pretty oily and has long life reserves. The Gulf Coast came in high, and then ‘bang,’ they’re down. Out here, if the casing doesn’t get holes in it, a well can last 30 to 40 years. There are some wells we drilled 40 years ago in the Spraberry and they are still producing.”

The founder of Henry Petroleum and, later, Henry Resources pointed out two major reasons why companies in the Permian have been slow to adopt the horizontal method. “It’s more expensive and it’s more difficult.”

A vertical well in the Wolfberry typically costs about $1.7 million to drill versus a horizontal well’s $7 million. “That’s a lot of difference,” Henry said. Another reason so many people have clung to the vertical well is the number of days required for drilling: 15 for vertical compared to 40 for a horizontal.

“We continue to get better and better at drilling horizontal and vertical,” Henry said. “The costs are still pretty high. When you drill vertically, you can have 40-acre spaces, which means 16 wells per square mile. When you drill horizontally, you have six or seven per square mile. Billions of dollars a year are going into drilling and completing wells in the Permian.”

Adding to the cost and the drilling time is the new procedure that has successfully coaxed more oil out of the ground: hydraulic fracturing. “Out here we tailor our frac’ing to our formations and what we’re trying to do,” Henry said. “Each formation is different.”

He explained that the frac’ing technique was discovered by the late George Mitchell, who tried different methods for 18 years before finding the process that worked.

Blong additionally pointed out that horizontal costs are higher partly due to the increased number of people required. “There are directional people on site, people delivering the tools, geologists, people delivering mud. There are more personnel involved on a horizontal well.”

And then there’s the cost of water with the frac’ing procedure. “The heart of Mitchell’s technique is increasing the amount of water by 10 to 100 fold,” Henry said. “We used to frac with 60,000 gallons. Now it’s up to 1 million gallons. It’s opening a lot larger area. Some of these tight formations become economical to drill.”

If the price of oil drops to $60 a barrel, Henry knows from experience that drilling won’t stop. “With new technology, we’ll find a way to drill at $60/barrel and have it be economical. We’re trying new technology all the time and risking things as independents. That’s the way you learn.”

Blong is one of those new independents willing to try something innovative. After working with drilling companies and associating with numerous experts, the Abilene native decided to try out some of his innovative ideas and started Octane Energy. “I see a tsunami of horizontal drilling work coming,” he said.

A numbers person, he monitors reports from Baker Hughes Incorporated and the Texas Railroad Commission as he explained why he uses the term “tsunami.”

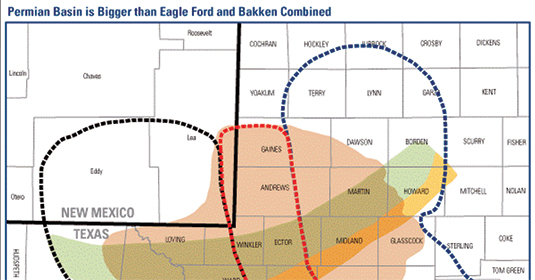

The Permian hit a high of 513 rigs during the third quarter of 2012, according to Baker Hughes numbers. That same quarter, the Eagle Ford reported 242 rigs while the Bakken was using 210. For third quarter 2013, the Permian reported 463 rigs; the Eagle Ford, 232; and 183 in the Bakken. The well count numbers also reflect much more activity going on in the Permian. For the second quarter of 2013, Baker Hughes showed 2,204 wells in the Permian with 1,050 in the Eagle Ford and 609 in Bakken.

The “tsunami” of drilling that Blong talks about may sound like a fantasy to some people but not to others. The Spraberry/Wolfcamp and Permian Basin were the focus of CNBC’s Mad Money, featuring host Jim Cramer, who interviewed Scott Sheffield, president and CEO of Pioneer Natural Resources on Oct. 8, 2013. Cramer talked about the “biggest play in the country, the Permian Basin in Texas and southeast New Mexico.” The largest oil producer in the area is Pioneer Natural Resources, a company that Cramer called “maybe a new major in this country.”

In that interview, Sheffield talked of the change in technology from drilling vertical wells for the past 30 to 40 years to drilling into the eight zones they have discovered in the Spraberry/Wolfcamp. “We’ll be doing most of the drilling. We’ll be ramping up to about 50 horizontal rigs over the next five years,” he said.

The company already is drilling wells that produce about 1,700 boe/day compared to previous wells that produced 100 boe/day. Sheffield pointed out that with the various zones they can drill into with horizontal wells, “there are eight Eagle Fords out there and eight Bakkens.” Pioneer owns over 70,000 well logs and over 1,200 feet of core, giving the corporation the basis it needs for continued drilling.

Blong’s company has designed its first “green” horizontal drilling rig that is under construction at Rig Tech in Odessa.

As the Permian chapter president of the International Association of Drilling Contractors, Blong has noticed what other contractors are doing in the rest of the country. “I wanted to see ‘rugged’ and ‘technological’ married in the design. I wanted to start something that is premier and organically Permian. There is no local who builds and operates a 1500-horsepower rig.”

Blong said he wanted a “green” rig that utilized environmental stewardship. He hired Joe Cervantes, who has 37 years experience in the drilling industry, as his chief operating officer. “Joe has been an early believer in drilling technology. When I came to Joe with what I thought was a safer, more efficient operation that would drill more wells, he said he thought it would work.

“We’re expecting the need for high spec rigs in the Permian to be from 75 to 125 over the next two to three years,” he added. “Across the board we are seeing a greening up of the industry. People are realizing they can do this environmentally safe work and it will save us. For example, we’re seeing water re-used. And we’ll see a greening up in the drilling industry. We need to meet environmentalists on their own turf.”

The demand for vertical wells, however, won’t disappear as several companies still prefer the less expensive route.

Jim Phillips, managing partner with Blue Line Drilling in San Angelo, says he is “not the typical drilling contractor. We’re niche drillers. We do shallow drilling prospects within 100 miles of San Angelo. We’re just plain ol’ meat-and-potatoes guys.”

Phillips started Blue Line in 2009 with Jerry McDonald. Both had worked for other employers, including Bandera, where they met in 1984. “We teamed back up in 2000 and then we just decided to do this ourselves instead of working for other people. My partner, Jerry, is the best downhole equipment man.”

As the company’s reputation spreads, they hear from small independents who say, “No one wants to talk to me about drilling my shallow wells.” Phillips knows that these small companies can have less (financial) exposure and profitability than the large firms. Sometimes those shallow wells can pay out quicker than expected.

Blue Line started with one shallow rig and now owns four that can drill from 2,500 to 10,000 feet. The first assignment was in Big Lake and since then the company’s rigs have drilled 200 wells, according to Blue Line’s website.

“There are a lot of small independents who can’t hire the big companies,” Phillips said. “They felt like a step-child. Being a small company, we can provide a better service. Many of our employees were people we worked with years ago. When they heard we were starting our own company, they came and asked for a job.”

Blue Line Drilling, described by Phillips as the “Wal-Mart of the drilling business,” doesn’t book long-term contracts. “We do not focus on a 20- or 50-well program.”

They talked Mike Swenson with MWS Operating of Stanton into being the first contract job. “I didn’t know him,” Phillips recalled. “Mike called and said ‘I’ll be a guinea pig and give you three wells.’ Since then, he has become more than just a customer. He had the courage to give us a try and we’re still working for him.”

When Blue Line started four years ago with one rig, the owners thought they might be able to purchase another one in two or three years. It wasn’t long, though, before they found themselves with four rigs.

“We had to search our souls,” Phillips said. “If we continued to grow, we would have to double our company’s size. That meant our employees would have to go further from home to do the work. Right now, our employees go home at night, since we focus on the 100-mile radius around San Angelo.”

Blue Line operates 24/7 with the employees working one of three eight-hour shifts. And if an employee needs to change a shift to meet a family commitment, that is fine with the employers. “They can swap shifts as long as the shift is covered.”

Phillips and McDonald decided not to continue adding rigs, but to become more independent by purchasing trucks and other necessary equipment. “We can move ourselves. We don’t have to stand in line and wait for a truck to do that. During our first year in business we had to stand in line and wait for independent trucking companies to fit us in.

“We capitalize the word ‘Independent,’” he explained. “We have our own mechanics, welders, and electricians.”

Blue Line Drilling’s motto says it all for many of the independents: “We’re here to stay.”