Safety Plan Hatched

BHP Billiton released report on major safety breakthroughs achieved in addressing hazards associated with tank gauging and thief hatch operation.

Tony Burke

A safety team headed by Allyson Faist was rewarded with the honor of top project in the health category at BHP Billiton’s 2016 ceremony for recognizing the efforts of employees who have excelled at enhancing the company’s commitment to health, safety, environment, and the community. The team comprised members of Billiton’s HSE, engineering, operations, and I&A departments, and achieved the net result of making BHP wellsites, and potentially those worldwide, substantially safer. The project’s executive summary summarized the scenario as such:

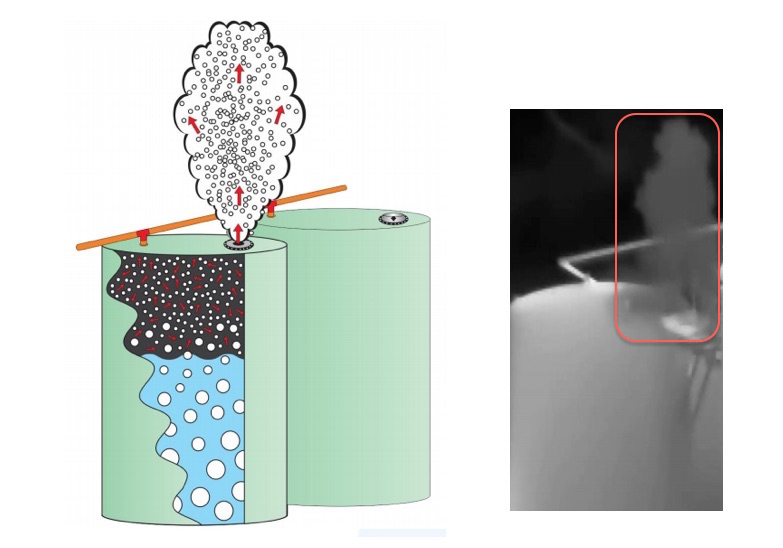

“Since 2010, at least nine fatalities in the United States oil and gas industry have been linked to workers measuring storage tank contents (tank gauging) and related activities at well sites. At least five of these fatalities occurred in 2014 alone, as reported by the Wall Street Journal. Each tragic incident involved opening a storage tank aperture, known as a thief hatch, on top of the storage tank, and measuring the oil and water levels with indicator tape.

It is vital to measure accurately storage tank contents at well sites. Gauging quantities determines the amount of revenue that companies, interest owners, and royalty owners receive for selling the product.

From August 2014 [through spring of 2015], a cross-functional BHP Billiton team known as the Thief Hatch Group has been performing extensive field research, analysis, and control to ultimately reduce potential hazard exposures of workers opening thief hatches on BHP Billiton Permian Production Unit (PMPU) well sites.

To date, PMPU has reduced these exposures by over 98 percent, from approximately 15,020 potential uncontrolled exposures per month to approximately 260 controlled exposures per month by trained and protected workers.”

The “Thief Hatch Group” implemented several changes in safety protocol, including requiring operators to wear self-contained breathing apparatuses, and then wait at the bottom of the access stairway until the initial high concentration of tank vapors dissipates. The following measures were identified and implemented:

- Barricaded the entrance to tanks and set policy of no entry on tanks unless authorized;

- Mandated the use of Automatic Tank Gauging (ATG), except for required API (American Petroleum Institute) hand-gauging requirements;

- Implemented processes to gather samples from controlled valve points lower in the equipment;

- Defined activities that required access to catwalks on storage tanks;

- Developed a written Standard Operating Procedure (SOP) and implemented a Repository Program for operations requiring access to the thief hatch;

- Met with oil truck tanker companies, which have the largest exposure numbers for hand gauging, to explain the need to eliminate hand gauging and use the ATG.

In a proactive move bound to score points for the United States energy production industry, the team’s rousing success story has made the rounds. These new processes and controls have already begun being put to use in making the oil and gas industry safer, creating a ripple effect far beyond the wellsites of BHP Billiton.

“Since implementing these stringent controls, no recordable incidents related to thief hatches have occurred at PMPU well sites. The team now aims to eliminate the remaining potential exposures by removing the need to open thief hatches altogether. Also, BHP Billiton has shared our data and information with industry and governmental agencies and was a critical part in the development of the Tank Hazard Alert issued to the United States industry.”

The team gathered significant data regarding oxygen and LEL (lower explosive limit) levels present at hatch openings. This data indicated that standing near the hatch opening exposed the operator to high concentrations of hazardous vapors. Oxygen levels between 19.5 and 23.5 percent are considered normal, while anything below 19.5 is deficient and potentially lethal. According to OSHA, environments with LEL levels of 10 percent or lower are considered safe. The report summarized the key findings as such:

- Oxygen deficiency was present when thief hatches were opened, regardless of the thief hatch opening method (“soda can” versus “flip”);

- Knowledge and understanding of wind speed and direction is crucial; plastic wind socks are ineffective tools for accurate measurement;

- LEL levels were identified at 100 percent when the hatch was opened and remained so for at least 200-to-430 seconds in every test, meaning the worker was engulfed in the explosive hydrocarbon range for potential flash fires or explosions.

In addition to fire and explosion risks, lighter hydrocarbon vapors have been documented as having narcotic effects, causing dizziness, nausea, and other potentially dangerous symptoms.

For Allyson Faist, even “borderline” issues were great cause for concern. The 98.3 percent reduction in exposure to the hazards of operating thief hatches has special meaning for her, in addition to the rest of her team. Faist’s father, an oil and gas engineer himself, passed away due to brain tumor likely caused by long-term exposure to hydrocarbon vapors.

While great strides have clearly been made, the research is ongoing, as the increase in hydrocarbon extraction through horizontal drilling produces a different suite of hydrocarbons compared with traditional drilling methods.

“The remaining two percent of exposures are being risk-managed through robust safety processes, including the use of barricades, a stringent respiratory program, and use of monitoring equipment with trained workers.

However, the team’s interest in worker safety is not limited to our operation in West Texas or other BHP Billiton operations. The goal of the team swiftly shifted to a desire to share what we discovered with the industry as a whole and change the way the oil and gas industry does business.”

As a result of their hard work, Faist and her team proceeded to work with NIOSH, OSHA, and the National STEPS Network to develop and distribute a Tank Hazard Emergency Alert to around 150,000 companies and organizations in 2015.

Tony Burke is a freelance writer and the assistant editor of PBOG. He can be reached at tburke@zacpubs.com.