Tablet Certified for Hazardous Locations

Juniper Systems, Inc. recently announced the availability of its nonincendive Class I, II, and III Division 2-certified version of the Mesa 2 Rugged Tablet. Called “Mesa 2 Hazloc,” the tablet is certified to perform safely in hazardous locations where explosive gases, liquids, vapors, dusts, or fibers and flyings may be present.

The Mesa 2 Hazloc is ideal for oil and gas markets and other industrial uses, such as LDAR, preventative maintenance, refueling, and asset management, among others. The Mesa 2 Hazloc features a full Windows 10 operating system, a large, 7-inch, IllumiView display for enhanced visibility, all-day battery life, and outstanding ruggedness with IP68-rated protection against dust and water. Also available on the tablet are a 1D/2D barcode scanner and UHF RFID reader, allowing for the rapid capture of data-rich readings.

“The Mesa 2 Hazloc is designed to not only improve productivity and efficiency when collecting data, but also to do its job safely in potentially explosive environments,” said Tom Francom, industrial market manager at Juniper Systems. “Juniper Systems prides itself on providing products with top-notch quality, and the Mesa 2 Hazloc is no different. The tablet performs reliably in any environment, and with its Class I, II, and III, Division 2 certification, users can feel confident using it in hazardous locations.”

Juniper Systems is now taking orders for the Mesa 2 Hazloc. To learn more about the tablet, please visit their website at http://bit.ly/Mesa-2-Hazloc.

About Juniper Systems:

Based out of Logan, Utah, and Birmingham, U.K., Juniper Systems designs and manufactures ultra-rugged handheld computers and provides field data collection solutions for use in extreme environments. Since 1993, Juniper Systems has provided innovative mobile technology to natural resources, utilities and public services, geomatics, agriculture, industrial, and military markets. For more information on Juniper Systems products, please visit http://bit.ly/28UGS33.

Spoolable Pipe For Low Pressure Applications

Polyflow, LLC., announced in June the commercialization of a new spoolable pipe product that is designed for transporting hydrocarbons at low pressures. The new Thermoflex Lite product fills the gap between HDPE pipe and Polyflow’s standard Thermoflex offering.

Thermoflex Lite pipe is designed for long, continuous runs for the transmission of hydrocarbons and other produced liquids. The pipe uses a proprietary one-step co-extruded production process, which includes a Nylon PA-6 liner to protect the HDPE pipe from hydrocarbon contamination.

According to Jim Moore, CEO of Polyflow, the manufacturing process creates a cost-effective durable pipe without the need to de-rate pressure specifications for hydrocarbons.

“Our customers love our standard Thermoflex pipe, but it just isn’t cost-effective for certain low-pressure applications. With our new Thermoflex Lite pipe, we are able to service this growing market with a rugged pipe product that is manufactured to industry-recognized standards,” Moore said.

“From a cost standpoint, we know that our customers are being squeezed in today’s environment of low commodity prices. The Thermoflex Lite product give our customers a solid choice that can meet their exacting technical specifications, performs well in the field, and is backed by the experienced Polyflow team of engineers and service personnel,” he added.

The Thermoflex Lite product utilizes either a mechanical or electrofusion process to ensure proper joining, field integrity, and fast installation. The pipe is designed for pressures up to 300 psi with hydrocarbons present, and long-term service temperatures up to 180 degrees Fahrenheit.

About Polyflow, LLC:

Polyflow is the leading manufacturer of flexible pipelines for transporting hydrocarbons, even in harsh environments. Polyflow’s Thermoflex piping is lightweight, fast, and easy to install and has lower ongoing operating costs than steel pipe, allowing oil and gas exploration and production companies to get wells flowing fast and increase profitability. Polyflow delivers superior service in the field, from modeling, installation and support.

For more information, contact Jeremy Hohn, Polyflow, LLC at 432.686.2001, or email jhohn@polyflowglobal.com.

Proxima Thermoset Resin Portfolio

Materia Inc., a leader in the development and manufacture of catalysts and advanced polymers, is pioneering the next generation of oil and gas solutions with Proxima thermoset resins.

Proxima resins provide reliable, practical, and economical solutions that solve major technology challenges in subsea thermal insulation, subsea buoyancy, and downhole tools. Proxima resins are extremely easy to process due to their inherently low viscosity and controlled cure profile. The resulting durable products are ideal for use in extreme environments. Compared with commonly used polymers, Proxima thermosets withstand the most extreme hot and wet conditions and provide excellent performance.

Proxima HTI resins for high temperature subsea thermal insulation provide an effective thermal barrier between high temperature flowlines and seawater. Proxima polymers maintain structural integrity in operating environments at water depths greater than 10,000 ft., and this advanced insulation technology can be rapidly and safely applied in the factory or the field.

Brian Conley, senior Proxima product development manager, said, “Materia’s subsea thermal insulation products offer full system integrity for high-temperature deepwater environments. The use of Proxima HTI polymers results in lower risk and better reliability for insulation of high-temperature subsea flowlines, field joints, and equipment relative to the alternative engineered solutions.”

Proxima STR thermosets are designed for use in syntactic foams in subsea buoyancy applications. These lightweight materials withstand the severe hydrostatic pressures of deepwater and ultra-deepwater environments while providing substantially improved buoyant support to critical subsea components. Ed Lehman, Proxima product development manager, said, “Proxima STR resins offer reliable manufacturing, state-of-the-art properties and improved long-term performance, delivering benefits throughout the value chain.”

Daryl Allen, Proxima product development manager, said, “Proxima HPR casting resins offer thermal stability and toughness with fast and easy polycrystalline diamond compact (PDC) or tricone drillability for many downhole applications. When long fiber composite performance is required, Proxima ACR infusion resins offer exceptional performance with fiberglass and carbon fiber. These bring improved thermal stability, corrosion resistance and reliability when compared to standard composite materials. Both the HPR and ACR systems provide superior materials that solve today’s downhole challenges.”

Materia supports its customers with application engineering services provided from its state-of-the-art prototyping and polymer testing facility in Pasadena, Calif.

Ultrasound Camera For Ndt Inspections

Imperium, Inc., in June, announced the availability of its latest ultrasound camera and rugged controller system, the AcoustoCam i700. Performing inspections from zero-degree up to seventy-degree shear, the AcoustoCam i700 can be used for improved inspections on not only straight beam applications such as composites and pipeline corrosion mapping, but also weld and TOFD inspections using the new angle beam functionality.

Imperium debuted the camera at the 19th World Conference on Non-Destructive Testing in Munich, in June.

The AcoustoCam i700 offers higher resolution C-scan images than either automated ultrasonic testing (AUT) or phased array systems. It creates images in flat or curved materials up to six inches thick and is fully compliant with most industry UT codes. The camera produces sub-millimeter images of an entire field rather than a single pinpoint—for better detection of pitting, cracking and other defects. Large area maps are created in real time and reviewed off-line via analysis reporting tools. As a result, the detection of flaws is increased while false positives are reduced.

The AcoustoCam i700 camera empowers companies in the oil and gas, aerospace, power generation, nuclear, and automotive industries with the ability to see what they couldn’t previously.

“Our customers tell us it is all about better pictures and reducing asset downtime,” said Bob Lasser, president and CEO of Imperium. “The quality and repeatability of the AcoustoCam i700 images allows customers to get a true understanding of any potential issues before they become disasters or public relations nightmares.”

A versatile tool that supports myriad applications, this new, real-time ultrasound is compliant with several procedures and codes, including:

- ASME Section V: NDE – Nondestructive Examination

- ASTM E317-06a: Standard Practice for Evaluating Performance Characteristics of Ultrasonic Pulse-Echo Testing Instruments and Systems

- ASTM 1324-11: Standard Guide for Measuring Some Electronic Characteristics of Ultrasonic Testing Instruments

- AWS D1.1: Structural Welding Code – Steel

- Boeing NDT Procedure: Part 4: 51-00-19 Ultrasonic Inspection of BMS 8-276 Solid Laminate Fuselage Structures for Damage (Ultrasonic Camera)

“The AcoustoCam i700 allows for inspections to continue without shutting down pipelines or pressure vessels—a huge win for oil and gas companies that are otherwise forced to defer production and associated revenue to verify historically unreliable pinpoint or AUT readings,” noted Danny Keck, an NDT industry consultant. “Pictures tell the real story. With the images delivered by Imperium’s technology, companies can make more informed decisions to address corrosion or other potential flaws.”

Inspectors are certified for usage of the i700 in three days—significantly reducing costs associated with training and hiring, as well speeding the process of getting the camera into use in the field. Imperium provides on-site camera calibration and training, as well as is available for custom procedure development.

Ruggedized Controller for Use in Nearly Any Environment

The AcoustoCam i700 features Imperium’s new, ruggedized controller that extends the use of the camera to extreme environments. The controller is IP-66 rated, has a 12-inch LED display, two swappable batteries, and a built-in handle, bumpers and kickstand. In addition, the unit features an integrated camera, speaker, microphone and multiple USB ports that support real-time video collaboration.

The enhanced controller is now also standard on new shipments of the AcoustoCam i600 and available as an upgrade to cameras already in use in the field.

NexTraq View Fleet Tracking App

NexTraq, provider of the most comprehensive, reliable, and easy-to-use GPS fleet tracking solution, in June, announced the launch of NexTraq View, its new supervisor mobile application. NexTraq View provides customers the power of real time productivity and enhances supervisors’ visibility of their fleet assets.

NexTraq View provides in-field supervisors with intelligent, real-time access to key information anywhere, anytime. With View, supervisors are able to access important fleet data while in the field and gives them direct access to the mapping and monitoring capabilities of the NexTraq Fleet Tracking solution.

“The development of NexTraq View is a direct response to feedback from our customers. Regardless of fleet size, field supervisors wanted improved insights to and manageability of their fleets,” said Jeb Scarbrough, VP of hardware engineering, NexTraq. “NexTraq View provides managers in the field a real-time view of their company assets and the ability to send jobs to workers without having to refer back to the office, which increases productivity and efficiency in an ever mobile world.”

The NexTraq View native application delivers full supervisor functionality. Users will be able to improve customer satisfaction through increased operational effectiveness, enhance visibility over real-time location of mobile workers, increase efficiency and improve productivity. NexTraq View complements the current driver mobile application, NexTraq Connect and seamlessly fits in with the award winning NexTraq platform.

As with all of the NexTraq mobile applications, NexTraq View is available to all NexTraq Solution customers.

SIMULTRA Retrievable Bridge Plug

Peak Well Systems, a leading specialist in the design and development of advanced downhole tools for well intervention, has reached another important milestone in the development program for its SIMULTRA range of retrievable bridge plugs. The range of available plugs has now been extended into 5-1/2-inch applications with the successful ISO-14310 V0 gas testing of the 5-1/2-inch tool in 20lb API casing.

The results of the testing showed repeatable zero bubble gas performance over a single test sequence that ranged from 175 degrees Celsius to 25 degrees Celsius and from 7,500psi above to 7,500psi below the seal—an outstanding result and one unmatched in the industry.

Additional testing of the same 5-1/2-inch SIMULTRA Plug to 10,000psi is anticipated to take place later this month. Peak was commissioned to conduct this testing specifically by a leading international oil operator that is interested in utilizing SIMULTRA technology to reduce cost in some of their challenging wells.

All tests were undertaken at Peak’s new state-of-the-art gas pressure testing facility located in Aberdeen and were independently witnessed and validated by a certified third party authority.

Robin McGowan, chief technology officer at Peak Well Systems, said, “Proving V0 performance across such a wide operating range in a single test run without the need to break testing into smaller temperature increments is a huge achievement and demonstrates not only the seal’s robustness but also the technology’s unique capability relative to traditional seals.”

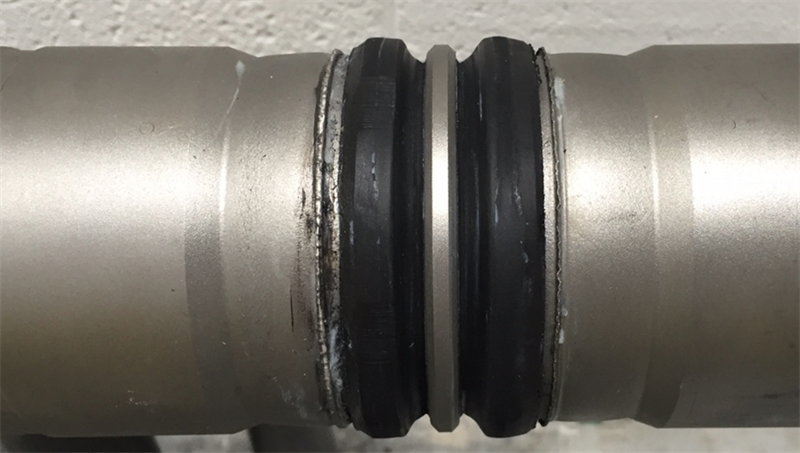

The SIMULTRA range was developed in response to an industry need for a high expansion, high performance plug suitable for gas wells and challenging applications. At its core is MetaPlex—a breakthrough hybrid metal-elastomer seal that delivers both exceptional performance and improved recovery reliability.

Officially launched in November 2015, Peak has now successfully achieved V0 certification for its 4-1/2-inch Plug in 11.6lb to 15.1lb casing as well as for its 5-1/2-inch Plug in 20 lb. which is also suitable for 23 lb. casing.

Peak aims to have the complete SIMULTRA range, which will include a 7” Plug, available for sale or rental by Q3 2016.

Peak Well Systems currently employs over 90 staff and offers sales, rental and related services through its Technology Centres and Rental Hubs worldwide.