The Fundamentals (and then some) of Formation Testing

By Julie Anderson

In times of frustration, coaches are famous for quoting the fundamentals: play your position, pace yourself, wait for your pitch, keep your eye on the ball, watch your form, save your energy.

Play, form, energy—when it comes to the oil and gas industry, these words certainly have special meaning, both in times of frustration and fruitfulness. Now that prices are creeping up bit by bit and more rigs are slowly but surely coming online, perhaps a look at one of the fundamentals is in order.

Formation Testing 101

The term “formation testing” covers a wide range of applications and means different things to different people,” said Steve McLaughlin, owner of Cardinal Surveys Company, with locations in Odessa, Texas, and Hobbs, N.M. Cardinal Surveys specializes in production logging, stimulation evaluation and formation pressure tests, http://www.cardinalsurveys.com/.

When a well is drilled, the section of the Earth’s strata that contains hydrocarbons, or oil and gas, is reached by the drill bit and made accessible to the surface through the well bore. But the oil and gas are not just found in a pool somewhere in the ground.

“Oil and gas are usually found embedded in dense rock, and they really don’t flow to the well bore all that easily,” McLaughlin noted. The rock strata where the oil and gas are found are called the formation, or more properly, the producing formation, and there are many tests that have been devised to help identify the nature of the formation and the amount of oil and gas held in the rock.

Formation testing helps the operator determine the amount of oil and gas in the formation, estimate how much oil and gas can be recovered, and estimate how long it will take to get the oil and gas out of the formation, McLaughlin said.

In Schlumberger’s textbook, Fundamentals of Formation Testing, the authors detail the objectives of well testing, as described in the book’s overview available at http://www.slb.com/resources/publications/books/fundamentals_formation_testing.aspx.

According to the text, well tests are conducted at every stage in the life of a reservoir, including exploration, development, production, and injection. Each stage comes with its own objectives, hardware, and design options. For example, at the exploration and appraisal stage, tests are performed with an open hole wireline tester, which measures pressures and collects fluid samples, and with the drillstring, which simulates production at the time of the completion.

During the development phase, the operator needs to better understand the hydraulic communications in order to relate the reservoir characterization to the geological model, according to the Schlumberger textbook. Formation testing at this stage predominantly consists of open hole wireline pressure testing. The emphasis is on static reservoir pressures, which are important for confirming fluid contacts and fluid density gradients.

In the production phase, the testing objectives shift from flow evaluation to reservoir monitoring, data collection for history matching of reservoir simulators, and productivity tests to assess the need for stimulation, as explained by the authors of Fundamentals of Formation Testing.

Methodology and Techniques

“Testing of formations is done using many methods and techniques,” McLaughlin said. Sometimes a core of the rock is recovered from the well and tested in the laboratory. Sensors to measure temperature, pressure, and flow are used for many tests, starting with the earliest life of the well, and continuing until the well is plugged.

Since many wells have more than one formation completed, tests are run to determine which formation, or zone, is producing. Fluids may also be sampled in the well bore down hole and brought to the surface for analysis, McLaughlin added. Specialized well logs with sophisticated sensors are conveyed in and out of the well on wire line or tubulars to measure data about the well formation, casing, and cement.

Specifically, the Drill Stem Test (DST) is run on a brand new well, McLaughlin said. After drilling, the DST tool is placed near the zone of interest, and the well bore is sealed with packer devices above and below. The DST tool analyzes the well flow and pressure when a valve is opened. From this data, the productive capacity and permeability, or the ability of the porous rock to allow flow, of the formation are measured.

“Permeability is a critical formation property to know,” McLaughlin emphasized. “A low permeability formation may have high formation pressure [formation energy], but production will still be limited. Low permeability formations are frequently frac’ed for this reason—to open up more formation rock for production.”

Wireline sampling, the practice wherein a sample container is lowered into the well to collect samples for laboratory analysis, tells the operator the chemical nature of the produced fluids, including the thermodynamic properties, McLaughlin said. This data is referred to as “PVT” data. The fluid properties are related to the formation properties and are used to characterize the way fluid flows from the formation to the well. The mobility and phase behavior are determined, which helps in planning how fast to produce the well, and the expected ultimate recovery of oil and gas.

Operators use injection tests to show how the formation responds when fluids are pumped into the well, McLaughlin stated. The pressure response is indicative of many formation properties. For instance, the fluid loss profile helps the operator find problems in the completion methods, including channels or other mechanical problems where other unwanted formations are affecting the well production. Unwanted water zones may be overshadowing the oil and gas production.

The formation parting pressure—that is, the point when increasing injection rates cause the formation rock to literally crack or fracture—is found by measuring injection rates and pressures in a series of steps, McLaughlin said. This procedure is called a “step-rate test” for this reason. Many regulatory bodies require a step-rate test as a part of the permitting process for injection wells.

The formation pressure response when transient flow tests are conducted communicates a great deal about the size and condition of the porous reservoir rock, McLaughlin offered. Transient tests are performed with a pressure sensor lowered to the formation. The well may be shut in for a build-up test; conversely, the well may be opened to flow for a fall off test. Low permeability wells sometimes are tested for days or weeks after the transient condition is started, and very high quality pressure sensors are used. Analysis software tells the story from the pressure data.

“The pressure response from one well the next may also help determine formation properties and flow paths,” McLaughlin said.

New and Improved

When it comes to low-mobility formations and heavy oil, conventional wireline formation testers are not always effective. Several years ago, engineers with Schlumberger developed a tool to increase reliability, according to Schlumberger’s Oilfield Review, http://www.slb.com/~/media/Files/resources/oilfield_review/ors13/spr13/03_dimensions.pdf.

(Insert Graphics)

Illustrations courtesy of Oilfield Review, copyright Schlumberger.

“Identifying mobile fluids and defining hydrocarbon columns can be difficult in complex formations,” wrote the author of the piece, entitled “New Dimensions in Wireline Formation Testing.” In the 1950s, the oil industry addressed sampling difficulties with the introduction of wireline formation testers (WFT), which were lowered on wireline logging cable to the targeted zone.

A newer version of the tool uses dual-straddle packers inflated above and below the sample point, or the station, to isolate the formation from the wellbore fluids and expose more of the formation for sampling (see illustration).

“Formation fluids are then flowed or pumped into the tool for capture and retrieval to the service,” according to Oilfield Review.

Another type of wireline formation tester, labeled a probe-type WTF, uses hydraulically operated arms to force a packer assembly against the borewall, according to Schlumberger. The probe, which is located in the center of the packer, extends into the formation. Then reservoir fluids flow are or pumped into the tool.

“The fluids are analyzed downhole, and samples may be captured while pressure is measured using downhole gauges,” the article states.

In the past, operators had to choose between the higher draw-down and reduced flow rate of a traditional probe and the larger flow rate of a straddle packer. As stated in the article, the disadvantage of a lower flow rate is length of clean-up time. On the other hand, although dual packers allow for higher flow rate than traditional probes, they create larger volumes of storage and may lose their seal because they cannot provide the necessary borehole wall support in unconsolidated formations.

Schlumberger engineers created the Saturn probe design, which, according to Oilfield Review provides the benefit of both a probe and a dual packer. In other words, the result is a large flow area to reduce the clean-up time and a packer-probe configuration to provide the support of the borehole walls, thus creating a more reliable seal.

“The Saturn 3D radial probe innovations allow operators to capture samples, perform downhole fluid analysis (DFA), and identify transient flow regimes in situations where they previously could not,” reported Oilfield Review. “These include low-permeability formations, heavy oils, unconsolidated formations, single-phase fluids close to the bubble point, ultratight formations, and others.”

Julie Anderson, based in Odessa, is editor of County Progress Magazine, and is well known to many readers of PBOG as the former editor of this magazine.

SIDEBAR or BOXED INFO

Wireline Testing

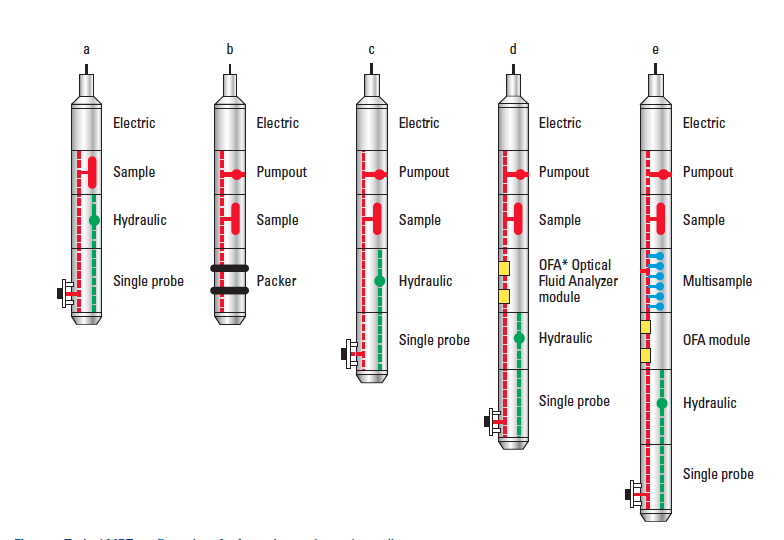

Wireline tests are performed mostly in open hole using a cable-operated formation tester and sampling tool anchored at depth while reservoir communication is established through one or more pressure and sampling probes. Figure 2 shows typical configurations for testing and sampling with the MDT* Modular Formation Dynamics Tester tool.

Insert Figure 2 on page 18 or page 4 as numbered on the actual page – Fundamentals of…in dropbox

Reprinted with permission, copyright Schlumberger, Fundamentals of Formation Testing, http://www.slb.com/resources/publications/books/fundamentals_formation_testing.aspx.

SIDEBAR 2 or BOXED INFO

Well Test Interpretation

The interpretation of well tests is one of the most widespread sources of dynamic reservoir data. Tests on oil and gas wells are performed at various stages of drilling, completion, and production. The test objectives range from simple measurements of reservoir pressure to characterization of complex reservoir features. Well tests can be classified either as single-well productivity tests or descriptive reservoir tests.

Single-well productivity tests are conducted to:

- determine well deliverability;

- characterize formation damage and other sources of skin;

- identify produced fluids and determine their respective volume ratios;

- measure reservoir pressure and temperature;

- obtain representative fluid samples suitable for PVT analysis;

- evaluate completion efficiency; and

- evaluate workover or stimulation treatments.

Descriptive reservoir tests are conducted to:

- assess reservoir extent and geometry;

- determine hydraulic communication between wells;

- characterize reservoir heterogeneities; and

- evaluate reservoir parameters.

Reprinted with permission, copyright Schlumberger, Fundamentals of Formation Testing, http://www.slb.com/resources/publications/books/fundamentals_formation_testing.aspx