Opinions and advice are in ample supply in our array of articles. These are the full versions of the “Drilling Deeper” news items that appeared in abbreviated versions in the print edition of the August PBOG.

EPA Gets Supreme Setback

Railroad Commission of Texas Chairman Barry Smitherman commended action recently by the U.S. Supreme Court regarding the regulation of greenhouse gases (GHGs). According to Smitherman, “Texas struck a blow for the Constitutional separation of powers envisioned by the framers of the U.S. Constitution.” In a decision handed down by the U.S. Supreme Court, Justice Antonin Scalia, writing for the majority, held that Environmental Protection Agency (EPA) was not required to regulate greenhouse gases as “air pollutants for all purposes” under the Clean Air Act, and that EPA’s rewriting of the statutory thresholds, for the allowable emission of GHGs, was impermissible.

“An agency has no power to tailor legislation to bureaucratic policy goals by rewriting unambiguous statutory terms,” wrote Justice Scalia. He added, “Were we [the Supreme Court] to recognize the authority claimed by EPA in the Tailoring rule, we would deal a severe blow to the Constitution’s separation of powers.”

Smitherman remarked, “As the former Chairman of the Public Utility Commission of Texas, and current Chairman of the Railroad Commission of Texas, I was honored to be a named Petitioner on this and other greenhouse gas cases. I applaud Attorney General Greg Abbott and the fine work that he, Solicitor General Jonathan Mitchell, and the entire Attorney General’s staff demonstrated in briefing and successfully arguing this case before the U.S. Supreme Court.”

Barry Smitherman

Business Tenets Applied to Life

Within the first five years of a small-business venture, about half do not survive, according to the government’s Small Business Administration. And after 10 years, only a third are still around. “Successful entrepreneurship hits the bull’s eye of the American dream, but most simply do not make it,” says veteran Texas businessman David M. Smith, author of The Texas Spirit, (TheTexasSpiritBook.com) “You don’t have to have extravagant wealth or a degree from Harvard to make it; a successful business requires essentially the same thing for a successful life—perspective.” In his new book, Smith reviews some common denominators for success.

• Aim at nothing and you always hit it. “If you’re like me—perhaps with a touch of ADD and someone who wants to do too many things than you have time for—this is a helpful aphorism,” Smith says. Not every idea that comes to mind should be pursued; be very selective with your time, and when you go after something, go full-throttle.

• You cannot win on the defensive in business or any other endeavor. Don’t think in terms of defense; instead, think of counterattack. To take a defensive position on anything means that you have conceded at least some of your position.

• Work toward optimal employment for everyone in your company. “At least once a year, I have a one-on-one discussion with every person in our companies – a renegotiation to hopefully renew employment for a longer period,” he says. “This adds an important personal touch and attention to detail.”

Of course, the same approach will offer an excellent return in your personal relationships, too.

• Keep in mind Union Pacific’s motto: “Safety is my responsibility.” Safety should always rank high in your priorities; it’s easy to take it for granted until a catastrophe happens. Texmark celebrates more than 25 years without a production-halting accident – a remarkable record in the industry.

• Organize projects, planning and profit action with at least three people, but never more than five. You need a point person for the meeting and at least two compatible partners – more than five people gums up the process. Meet weekly; the point man should set priorities and is most responsible for action.

• People chemistry is more important than process chemistry. Just as you must have a process for making chemicals built around operating conditions that are best for the desired chemical products, so too should you have the right chemistry of people working together. The right chemistry is trickier than you think.

• Promote voluntary participation regarding medical benefits and thrift and savings plans. It’s always best to put individuals in charge of their health and financial destiny—to let people consciously choose their plans. Monolithic systems arbitrarily imposed by institutions are the beginning of stagnated individual responsibility.

David M. Smith is the author of The Texas Spirit, (Halcyon Press, 2014, thetexasspiritbook.com). He’s the founder and owner of Chemical Exchange, Inc., and Texmark Chemicals of Galena Park, Texas. An El Paso native, he attended the University of Texas in Austin. Early in his career, he moved east to Houston and established himself in the petrochemical industry. His new book, The Texas Spirit, features a series of essays about the ways in which the United States can benefit from Texas’ example, including economic models and moral fiber.

David M. Smith

Creating a Winning Culture

If you’re the CEO of a company, the realization that much of what you do can be copied by your competitors may be distressing, but veteran sales manager, consultant, and business speaker Jack Daly says not so fast. “Sure, your competition copy what they can, but there are two things they can’t: your people and your culture,” says Daly, author of Hyper Sales Growth, (jackdaly.net) “I specialize in corporate coaching and sales, the latter of which really counts on the talent and sustained motivation of the sales force. Even your best salesperson needs that extra shot from time to time, and the best way to ensure a driven team is to create a culture that fosters the results you want.” Some companies are outpacing their competition because of their culture, including Southwest Airlines, Zappos and the Virgin Group, says Daly, who offers these tips for growing a business culture that inspires loyalty, engagement and the high performance those qualities produce.

• Start new hires on a Friday—and with a big welcome. Many managers think new employees should start on Monday – the day when their new co-workers are facing a long to-do list for the week. Consider starting them on Friday, when the office is a bit looser. Also – how about throwing the new hire a welcoming party? Many offices hold going away parties for departing employees, but it makes more sense to put this enthusiasm toward the person with whom you’re making a commitment, rather than the person who’s no longer working for you.

• Recognize accomplishments by putting it in writing—handwriting. Typing emails and instant messaging is clearly much more convenient, which is why an employee who deserves special attention will recognize the extra effort behind a hand-written note. A letter has that personal touch; the receiver knows that the manager or CEO has taken some time and effort to create a special communication just for him or her.

• Provide lunch—for free. “One of my clients started with just 10 employees, and each day one would bring in lunch for everyone,” Daly says. “As the company grew to several hundred employees, the CEO found that free lunches were so beneficial, the company now hires a caterer to maintain the boost in culture it provides.” While many may cringe at the expense, employee appreciation outweighs the cost, Daly’s client says, and it keeps people engaged within the office, rather than having employees leave for lunch.

• Flatten the privilege structure. It’s not a good idea to create anything resembling a class system, including special parking for upper management. “I was the No.1 salesmen at one company, but I always preferred to park with the others,” Daly says. “I’d come in at 5 a.m. and noticed that those with reserved parking arrived significantly later than those who parked in unreserved spots.” Parking should be on a first-come, first-serve basis. Upper management shouldn’t feel too entitled or privileged above other employees.

Jack Daly (jackdaly.net), author of Hyper Sales Growth, is an expert in sales and sales management, inspiring audiences to take action in customer loyalty and personal motivation through explosive keynote and general session presentations. He draws upon more than 20 years of business experience, with several successful stints as the CEO of fast-growing companies. Daly has a bachelor’s degree in accounting and an MBA. He was a captain in U.S. Army and is an accomplished author, with audio and DVD programs.

Chemicals Simplified

A product offering to the oil and gas industry—an application called Enbase Mobile—is described by its creators/producers as being able to “untangle complex chemical treatment activities, dosages, and record keeping for large operators,” thereby reducing chemical-related well failures and lease operating expenses (LOE).

Enbase Energy Technology describes its impetus for creating the application, starting with an industry scenario they’d seen too many times:

A sizable, publicly traded operator active in the Permian Basin and Midcontinent region was plagued by problems with its chemical treatment program. In this case, the problems affected more than 1,000 wells and related production equipment, all situated in the Permian Basin. Poor communication with chemical vendors meant a lack of visibility with regard to which wells were treated and/or sampled, how they were treated, and when they were treated. Moreover, the situation led to inefficient record keeping and billing. Despite initial impressions that wells were being sampled and treated, many wells were out of compliance, a condition that led to frequent, expensive well workovers and wasted chemical treatment dollars, both of which increased overall LOE and chemical-related downtime.

Well workover costs are the highest discretionary component of this operator’s Permian LOE, followed only by the cost of the chemical program itself. The high percentage of Permian Basin well failures that are chemical-related meant that the two cost components are directly related. Change was critical in order for the operator’s production engineers and operations managers to meet their dual objectives of reducing costs and increasing production.

Faced with this situation, the operator challenged Enbase Energy Technology (ENBASE) of Houston, Texas, to extend its Enbase Mobile application, already deployed in oil field service and lease operating environments, into the chemical treatment arena. The opportunity was, in short, to put everyone on the same page—chemical truck drivers, technicians, account managers, the Operator’s production engineers, operations, internal chemical management group, as well as accounting staff—by making it possible to track, document, and communicate a single, accurate version of chemical-related events in the field.

As an oil- and gas-only provider of field service mobile applications, ENBASE took the challenge. The Enbase Mobile – Chemical application for the Operator went from conception to the field within 2.5 months. Once implemented, chemical drivers were reporting all chemical treatments and sampling activities in near/real time, with geotagging, time stamping, full online-offline functionality, and automated data syncing to and from the Operator’s asset and production management software systems, giving the Operator greater clarity into what was taking place in the field.

In fact, during the first week of implementation, when traditional spot checks were initially reporting “no problems” with the Operator’s wells, with “all treatments on schedule,” 83 wells were actually found to be out of compliance (i.e. off-schedule). With Enbase Mobile, the Operator saw results almost immediately; by week five, not a single well was out of compliance and all sampling and treatments were up to date. Enbase Mobile – Chemical has enabled the Operator to gain control of its chemical program and the Permian Operations group is starting to see material reductions in well failure rates.

The High Cost of Well Failures

Permian Basin wells, of course, often produce with a high tendency for paraffin buildup. If wells are not chemically treated regularly for paraffin, they may go down due to high pump loads, or go down on high pressure alarm at the flow line. Moreover, if the wells are not sampled and treated for corrosion at regular intervals, they may experience corrosion-related failures, necessitating expensive repairs or workovers and resulting in more downtime. Paraffin clean-up also leads to timely workovers, while corrosion leads to replacing of equipment (as much as 80 percent of tubing string and rods).

The Operator had an unacceptable failure rate for these wells. Although a chemical treatment schedule was in place for every well, 70 percent of failures were directly chemical-related, requiring expensive workovers that were unreasonably driving up LOE.

With the cost of workovers ranging from $70-$90K per well, and the loss of production averaging as much as $15K per well over a five-day workover for each well, the economic impact was immediate and significant. Eliminating the issues of missed or mis-dosed treatments was critical for the Operator from the cost, operations and production perspectives.

Ineffectual Communication Led to Wasted Dollars

Prior to contacting ENBASE, the Operator faced a complex set of problems with the management of its chemical program in the Permian Basin, all stemming primarily from ineffectual communications and inefficient electronic data sharing.

Records were kept in cumbersome spreadsheets with “bad data” that didn’t match field operations, making it a constant challenge to interpret data consistently and ascertain exactly what happened in the field.

This created its own set of problems. For example, a well may not have been sampled as scheduled, which might cause the Operator to miss a potential bacteria issue that needed immediate treatment. Treatments might be late or missed, or over/under-dosing might render a treatment ineffective. In the case of corrosion inhibitor, a missed treatment could in turn cause a rod to break or create a hole in tubing, leading to the need for a costly workover.

This confusion was further exacerbated as the operator routinely brought wells offline for maintenance and then put them back online or added new wells, but with no effective way to communicate this “live asset status” data to the chemical vendors. Because chemical drivers received updated well schedules manually and periodically a monthly basis, but wells could be taken offline or brought online on a daily basis, new wells might go days without treatment, or down wells receive unnecessary treatments. The lack of real time communication led to wasted dollars and caused inefficient well operations.

Lack of Accountability Also Spreads Chaos to Other Asset Areas

The operator also lacked clarity as to what was happening at batteries and headers. For example, treatment rates at headers should vary depending on the volume of barrels of oil equivalent (BOE) produced, with a high-producing header receiving potentially more treatment chemicals. However, the operator was not capturing the pump rates at batteries/headers, so the chemical vendors were administering the same dose at each header regardless of production.

There was also an inventory mismatch. In theory, headers and batteries being treated continuously, vendors might report pumping 2 gallons / day (for a total of 60 gallons per month), but then would record inventory for 100 gallons each quarter. The numbers weren’t adding up.

Obviously, with so much data switching hands and so many “versions of the truth,” it was impossible to hold anyone accountable for treatments in the field, let alone for the chemical program as a whole.

Seeking a solution, the operator tried options that included rotating vendors, or dividing up the Basin and using multiple, competing chemical vendors at the same time. None of these options solved the problem.

In short, the Permian team was operating blindly, employing a reactionary, “brute force” approach rather than operating “by exception” in a proactive, data-driven manner. The cost of operations, coupled with the substantial maintenance costs, created an urgent need for the Operator to find a solution.

Solution Impact

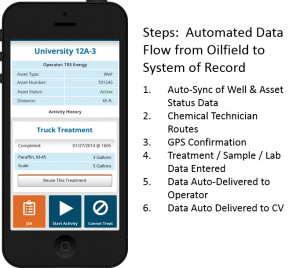

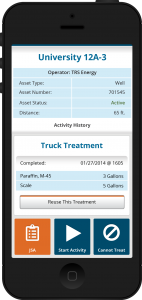

Key to the solution for the operator, the Enbase Mobile application provided 24/7 access to all chemical program information, anytime, anywhere, regardless of connectivity. This mobile application runs on any modern smart phone, tablet or laptop, and with its intuitive interface, is simple to navigate – even by field service personnel who may traditionally eschew technology.

The Enbase Mobile application is also integrated with the operator’s source systems, enabling chemical technicians to electronically receive up-to-date information on well/asset status (i.e. is the asset online and should it be treated or sampled), and can confirm treatments, pump/dosage rates, sampling activities, and tank level inventories within seconds. Moreover, chemical drivers and technicians are geotagged at the asset’s location and all activities are electronically date/ time stamped, so the operator has complete assurance that field activities are taking place as promised.

All of this information is transmitted electronically and automatically back into the operator’s source systems in near time and without any manual or double data entry. As a result, all vested parties have real-time visibility into chemical inventories, usage, and deliveries, making it easy to confirm treatments and delivery, and monitor inventories and usage rates.

Implementation of the Enbase Mobile solution immediately resolved a number of operational issues for the operator. Most obviously, the mobility aspect completely resolved the live data transfer issue. Now asset status changes (i.e., assets coming online or offline) are transferred to vendors on a daily basis, and in turn, treatment reports from vendors are received nightly; as a result, the operator gets a complete and accurate picture each day of which assets were treated and the amount of treatment, with assurance that treatments actually took place.

Of equal importance, the Enbase Mobile solution gives the operator the ability to operate by exception, whereby the operator sends its chemical vendors an electronic feed of wells that are out of compliance and by how many days, so those assets can be treated as soon as possible. Instead of a “milk run” approach, vendors know exactly how to prioritize chemical treatment deliveries; all assets are in compliance unless reported otherwise.

Perhaps most importantly, vendors are kept accountable because Enbase Mobile ensures they know exactly which assets need to be treated, and whether any assets are out of compliance.

Given this transparent accountability, the operator is better able to evaluate vendor performance. There is no longer any guesswork, because Enbase Mobile provides the data on which vendor is delivering the right dose at the right time, and which has missed treatments. This provides the operator leverage and greater negotiating ability, ensuring vendors perform as agreed and enabling the company to award work according to vendor performance and value.

Economic Results: Driving Down Failure Rates

Failure rates have significantly improved with the implementation of Enbase Mobile at the operator’s Permian Basin operations. While the exact cost savings are currently being quantified, the operator reports receiving much better data, and anticipates improvement in additional metrics now that the company has the quality data necessary to make these determinations.

Enbase Mobile capabilities have simplified data collection, tracking and reporting, including tracking failure rates, causes of failures, and cost due to failures. Even more, the information management capabilities of the application enabled the operator to rapidly bring more than 80 noncompliant wells to zero wells out of compliance in a matter of weeks.

Because of the ease of use and success in implementing the program, the operator is expanding Enbase Mobile across all its operating regions, including the operator’s sizeable operations in the MidCon. In addition, the operator sees significant potential for Enbase Mobile for other E&P field operations such as new construction, haul-offs, maintenance, repair, overhauls, workover, etc.

As stated by the operator’s production engineer, “We see a tremendous benefit to expanding Enbase Mobile to many other areas, and see opportunity for Enbase Mobile to provide effective cost-containment and contractor management. In particular, any field-level activity that is tied to billing can be significantly streamlined with the implementation of Enbase Mobile.”

Wherever there’s a communication gap between engineering, operations, field-level service providers and accounting, Enbase Mobile bridges the intersection of these three areas so that:

- Engineering and operations have perfect clarity in terms of what’s happening in the field.

- Operators and vendors can collectively “operate by exception,” as partners and with confidence.

- Operators pay only for work that’s actually done – no treatments are missed; no dollars are wasted.

To learn more about Enbase Mobile for E&P, Chemical, Midstream, Compression, Subsea, and Energy Services, visit www.EnbaseSolutions.com, or contact ENBASE directly at 713-568-2835.