In enhanced oil recovery, a fluid—typically water with various additives—is pumped into an injection well to force additional oil out of the reservoir. This technique can double the amount of oil extracted from a well, increasing oil availability and lowering costs. However, the conditions in the injection fluid are often extreme, and the behavior of the additives are not well understood.

Nonionic surfactants are molecules with both hydrophobic and hydrophilic components, which lets them interact both with hydrophilic liquids like water as well as hydrophobic liquids like oil. This surface-active property makes them invaluable in enhanced oil recovery, where they can be used to greatly increase oil yields.

During the American Crystallographic Association’s 72nd annual meeting, held recently in Portland, Oregon, Thomas Fitzgibbons, of Dow, detailed how nonionic surfactants behave under the high-pressure conditions found in oil wells. His session was titled “Understanding Self Assembly Under Reservoir-Like Conditions.”

An oil well often has several unique challenges when looking at surfactants for enhanced oil recovery,” said Fitzgibbons. “The water in the well is often a brine with a high salinity. The temperatures are also high, and pressures can reach upwards of 10,000 psi. These factors all have an effect on surfactant systems.”

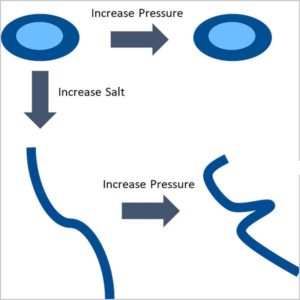

Adding nonionic surfactants to the injection fluid can help in several ways. The polar-nonpolar nature of the surfactant molecules can increase the solubility of oils in water, and surfactants can also interact with rock formations to increase extracted oils. At high concentrations, surfactants can form nanocolloids called micelles, which are usually spherical but can transition to wormlike in shape under conditions found in oil reservoirs.

“Wormlike micelles are known to greatly affect the viscosity and therefore efficiency of a fluid in enhanced oil recovery applications,” said Fitzgibbons. “We have shown for the first time that when conditions exist where the micelles elongate to form worms, that pressure can affect the stiffness of the micelle worm.”

Fitzgibbons and his team studied surfactant micelles at the high-pressure Small Angle X-ray Scattering setup at the Cornell High Energy Synchrotron Source. This arrangement allowed them to emulate the conditions found inside injection wells and in oil reservoirs. The researchers hope to use this information to improve injection efficiency in the future.

Nonionic surfactant molecules, alcohol ethoxylates, self-assemble into spherical or elliptical micelles above their cmc at ambient conditions in deionized water. However, when salt is added to the solution, the micelles extend into rods and wormlike colloids. Through the application of pressure these wormlike micelles compress and their persistence length is decreased. Image credit: Thomas Fitzgibbons