Click here to listen to the Audio verison of this story!

Liquids emitted by oil wells are by nature harsh and corrosive in most cases. That includes the crude oil and the associated water. Between paraffin buildup and corrosion breakdowns, the oil industry must constantly fight to keep the liquids flowing and inside the infrastructure.

Two of the top solutions involve chemical treatments and pipeline lining. Both options can help with both issues. And lining a pipeline with thermoplastic material requires a different approach to inspections.

In this account we look at a national chemical provider, Centrium, and a pipeline lining company (also with national reach), United Pipeline Systems. United Pipeline provides high-performance thermoplastic internal lining systems for many industries, including oil and gas in the Permian Basin. Also getting our attention is Pipeline Inspection and Condition Analysis Corporation (PICA), which handles lined pipeline inspections.

Lining them Out

United Pipeline System’s Tite Liner® is unique in that the liner is made larger than the pipe it is lining, said the company’s Director of Business Development, Cordell Brown. “The outer diameter of the liner is larger than the inner diameter of the host pipe, so it’s not just a smaller pipe slipped inside of the steel pipe. It actually fits tightly against the host pipe inner wall.”

In the installation process, the liner is rolled down to slide into the host pipe, the liner naturally attempts to rebound to its original dimension, allowing it to fit tightly against the host pipeline’s inside wall.

That design allows Tite Liner to be thinner than other options, so it does not significantly reduce the inside diameter (ID) of the host pipe, which might otherwise reduce the flow capacity. Its snug fit also means the host pipe itself is holding all the pressure, so it has no effect on pressure capacity. Brown said they have lined systems of up to 7000 psi capacity.

History

Brown said Tite Liner began in Edmonton (the company’s headquarters) in the 1980s. It addressed the fact that a loose liner does prevent corrosion, but “it can’t handle pressure, and it expands and contracts in the pipe and moves around,” he said.

“So, the idea was to use this tight fitting, compression fit liner,” which is now known as Tite Liner. They began with CO2 pipelines from Colorado to an oilfield near Snyder, for use in enhanced oil recovery (EOR).

Now, in addition to oil and gas, Brown said they are increasingly seeing clients in industrial and municipal applications. Mining is big, too. “We have probably our largest operation, people-wise, in Chile. We have a big footprint there where liners are used for abrasion control so that steel pipes don’t wear out. They put liners inside of them.”

Liners go into pretty much all types of systems, including crude and refined products of many types—but still their main application is in produced water pipelines. This sector is growing because of greater awareness of the need for lining. But its growth also can be seen as a kind of fallout from the designation of Seismic Response Areas (SRAs) ordered by the Texas Railroad Commission.

With growing sections of the Permian off limits to saltwater disposal wells (SWDs), produced water must be sent farther and farther out—through pipelines. More and more water is going to Upton County and other southern Permian areas.

Today a large percentage of pipe receives a liner before installation, which is the most efficient procedure. In recent years most end users have realized how economically efficient it is to line it first instead of after there’s been a leak—although United does get the occasional panic call.

Brown said, “Some operators or owners will have an issue where they expect the pipeline to last 20 years, and then in two or three years they’re getting holes in the pipeline. In that case, United can rehabilitate the pipe with a liner. In many cases we install liner in new pipes to prevent these issues.”

Expect to Inspect

Lined pipes still need inspections, but a lining acts as an insulator, which makes older methods of pipeline inspection obsolete. To solve that issue PICA has developed new methods, said the company’s Director of Business Development, Kevin Weeks.

Magnetic Flux Leakage detection, or MFL, was very effective in finding issues in unlined pipe, he said. It’s also fast, “but it does require intimate contact with the pipe wall to get that data,” which is impossible with a liner installed.

Instead, PICA uses “RFT or remote field testing, which is creating an electromagnetic field that nondestructively penetrate liners to get the condition of the metallic components of the pipeline.” With RFT, “We can non-destructively see through the liner to get the integrity or the condition of the metallic components of the pipeline.

To deploy this, PICA usually uses what Weeks called “a dual tethered setup” involving winches at either end of the area being tested. “We’ll winch the tool back and forth to capture the data that we need at a very specific rate of speed.”

Does a liner reduce the frequency of pipeline inspections? Weeks said that is completely up to the operator, and may depend on regulatory issues, especially for interstate lines that face federal scrutiny. He stressed that regular inspections can pick up any trends—deterioration that may not yet require action but indicates a need for continued monitoring.

Like United, PICA has inspected pipes carrying everything from crude oil to refined products to produced water and beyond. They also see more and more business from industry and municipalities.

Chemicals

Using chemicals to control oilfield corrosion and paraffin goes back more than a century. Early methods used tar and pitch to try to slow corrosion.

In the last few years technology has improved both the efficacy and the delivery of chemicals, but much of the latest and greatest is confined to tier one companies with big budgets and far-flung supply options.

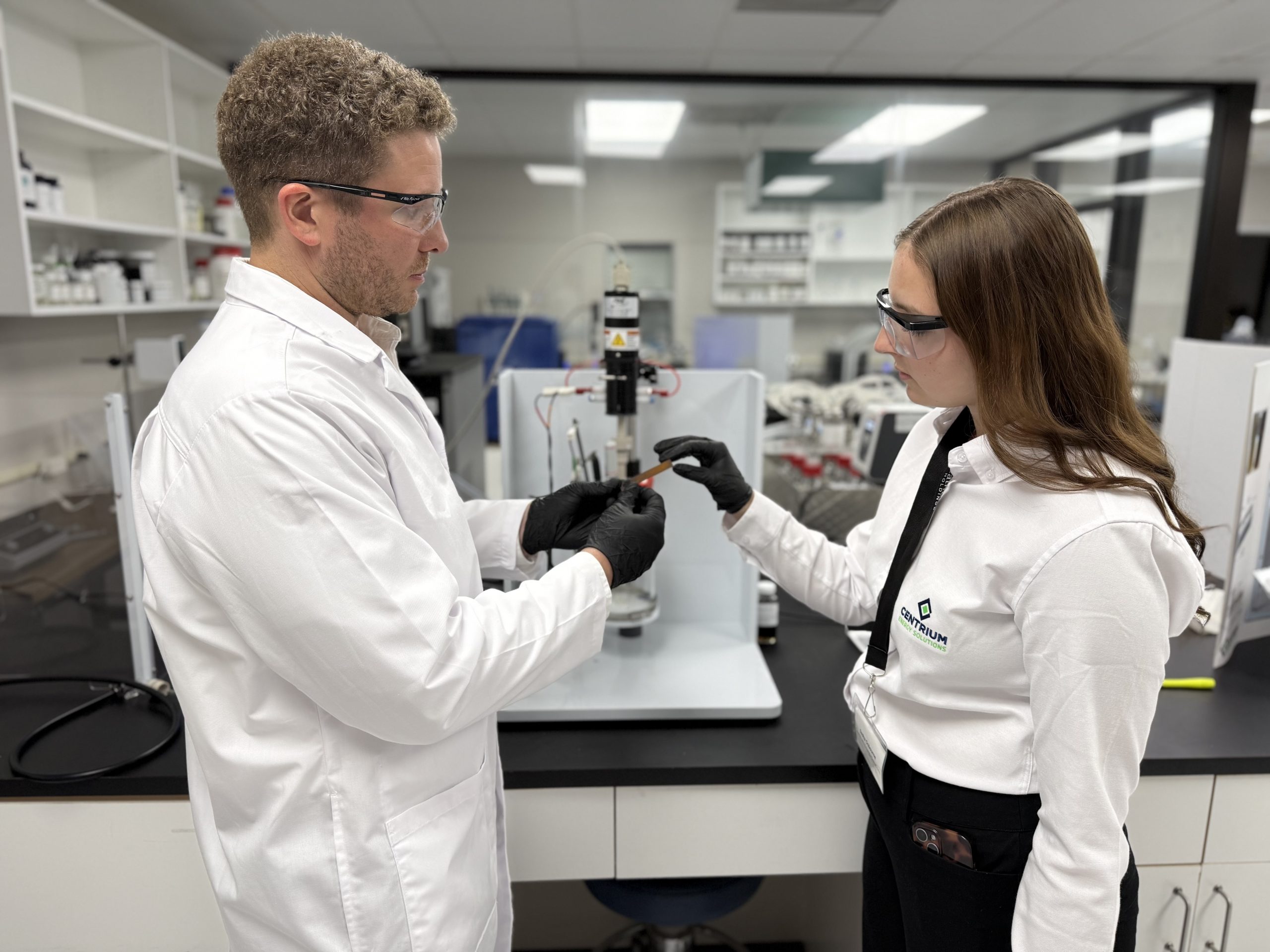

Centrium Energy Solutions was founded recently to partner with small to medium oilfield service (OFS) and chemical companies to better compete, said Jonathan Rogers, the company’s general manager. “We built Centrium to level the playing field, giving independent OFS providers access to the same speed, supply security and technical resources the majors enjoy.”

One key to their success is onshoring the supply chain, which does two main things: it assures the best quality control, and it eliminates supply chain and tariff issues associated with imports.

Better than Chick-fil-A

Backing Centrium is Cathedral Holdings, which Rogers described as “a 28-year-old U.S. distributor with deep roots in specialty chemicals.” The parent company’s model over the years has involved more than just supplying chemicals. They “partner with formulators to boost performance, improve product quality, and enhance cash flow” in industries like personal care and industry.

Rogers reported that this model has earned the company higher customer satisfaction ratings than Chick-fil-A. Cathedral Holdings’ international partners encouraged them to bring that model to oil and gas.

He said Centrium can access about 5,200 raw material chemicals, and more if needed. Onshoring the supply gives them more control over timelines, pricing and quality than is possible from overseas suppliers. “Samples arrive in 48 hours, not weeks,” he said. That confidence allows customers to reduce inventories because they can depend on quicker resupply, leading to “faster deployment, and better cash flow.”

Evolution of Customer Needs

In a sea of M&A activity, Rogers said, uncertainty rules, especially for overseas suppliers. “At the same time,” he said, “customer expectations are changing. Price per pound is no longer the only metric. Performance, lead time, and technical support now matter just as much. Service providers want more value per drum, not just the lowest price.”

Toward that end, he said the company screens and evaluates formulas to help customers get what they need, and to “close technology gaps.” Instead of just offering a fast-food menu, they research and advise on special orders. That doesn’t always make them the cheapest, but Rogers said that’s not their goal. Instead, it is “to be the partner that adds the most value.”

Value is a key component of everything oil-related today, as costs and challenges continue to rise. Protecting existing pipe and enabling it to flow oil, water, or other oilfield liquids at full capacity is an ongoing process.

Paul Wiseman is a longtime writer in the energy industry.