by Bobby Weaver

The oil and gas industry produces many products ranging from fuel to plastics, but few are aware that the extraction of rare gases are an important, albeit a small, part of that activity. Perhaps the most important of those gases is helium. When the term helium is mentioned, the vision that comes to mind is usually one of party balloons filled with the lighter than air gas causing them to waft gracefully across the sky to delighted screams from pint sized birthday attendees. That image is far from overall reality because helium plays a crucial role in a variety of areas including atomic energy production, medical procedures, missile technology, shield-arc welding, and low temperature physics technology.

Helium, the second most abundant gas in the universe, is listed on the periodic table of elements under the group name of Noble Gases and has an atomic number of two. It is identified by the symbol of He. Helium makes up trace amounts of about .0005% of the earth’s atmosphere. The gas is produced by the decay of radioactive elements in the earth’s crust, but it is not gravitationally bound to the earth so it does not accumulate in the atmosphere. Further, helium is an inert gas that does not easily combine with other elements; consequently, there are no known compounds that contain the element. That leaves the only viable source of commercial quantities of helium to be that trapped within natural gas deposits.

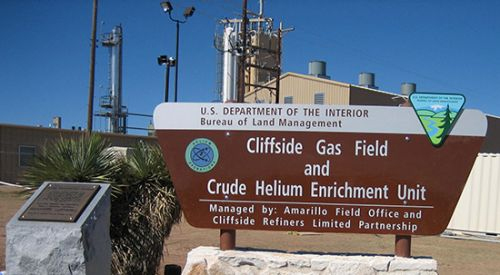

The Cliff Side (also spelled Cliffside) gas field, lying near Amarillo, Texas, also has been referred to as the National Helium Reserve.

Helium was discovered during an eclipse of the sun in 1868, when astronomers identified an unknown band of gas surrounding the sun. It was to be 27 years later, in 1895, that the element was proven to exist on earth. That was when Sir William Ramsay of Great Britain discovered it in a uranium-bearing mineral called cleveite during research to find a commercial source of argon. Over the next few years helium was found to be widely distributed across the face of the earth, although in minute quantities, and none was known to exist in natural gas.

All that changed in 1905 with the investigation of a natural gas well at Dexter, Kansas, brought helium out of the realm of a scientific curiosity into the reality of (potentially) commercial application. It started when the high level of incombustibles in the gas from the Kansas well prompted the state geologist to send samples to the University of Kansas for analysis. University chemistry professors Hamilton Cady and David McFarland discovered that the natural gas contained 1.84% helium and over the next several years they found similar concentrations at various other points in the region. Meanwhile, experiments proved that natural gas with concentrations in the range of one percent or higher made the commercial production of helium from natural gas sources a reality.

By 1915 with WWI in full swing the need to replace the highly explosive hydrogen with the inert nonexplosive helium as the gas to inflate military dirigibles and balloons became a high priority. Developing a viable commercial supply of helium fell under the auspices the U.S. Army and Navy. The army built the first experimental helium extraction plant in 1915 at Petrolia, Texas, in Clay County and soon thereafter the Navy built two more experimental plants north of Fort Worth. They all used gas from the Petrolia field, which provided natural gas with a helium content in the one percent range. In 1921 shortly after the end of the war and as a result of those first experimental operations, the Department of the Navy opened a large-scale commercial helium extraction plant near Fort Worth and the three smaller experimental facilities were dismantled. In 1925 the operation of the Fort Worth facility was transferred to the U.S. Bureau of Mines.

The process of helium extraction used at the Fort Worth facility has remained little changed since those days. Essentially it involves subjecting natural gas to high pressures creating a temperature drop that causes the gas to liquify. In the first phase of the operation the temperature is lowered to approximately -250 degrees Fahrenheit, a level that causes all the gas to liquify except nitrogen and helium, which have lower freezing points. Then the liquid natural gas is separated, returned to its gaseous state, and sold as fuel. At that point the gaseous mixture left over, termed crude helium, contains about equal parts helium and nitrogen. In the final phase the temperature is once again lowered in a procedure similar to the original process, thereby removing the nitrogen from the crude helium, leaving only pure helium of approximately 98% purity. The resulting process is then stored for shipment at a pressure of about 2,200 to 2,500 pounds per square inch.

By the time the Fort Worth plant began operations, the Petrolia field, which had been supplying natural gas to the towns and cities of North Texas, including Fort Worth and Dallas, since its discovery in 1907, was much depleted. The Bureau of Mines was well aware that there was not enough gas to keep the operation running beyond a few years. Consequently they began an intensive campaign to find some other area that would assure a long term supply of helium-rich natural gas. To further complicate matters, in addition to containing more than the 1 percent volume of helium, the gas field chosen would have to provide a sufficient supply of gas to assure long term viability, have a high rock pressure, be close to a market for the leftover natural gas, and be near transportation facilities capable of transporting the refined helium.

Ultimately the Bureau of Mines ran samples on more than 3,000 gas wells scattered across the Southwest. One of the first considered was the Nocona oil and gas field in Montague County, Texas, which was near the existing Fort Worth facility. Unfortunately, it, like most of others, did not contain the long-term production capabilities necessary for the project. By 1926 the Bureau had settled on the Cliffside structure or Bush Dome in Potter County, Texas, a few miles west and north of Amarillo, as the most likely prospect. Investigation indicated that the gas field covered approximately 50,000 acres, helium concentration was at 1.8 %, the structure was isolated from the rest of the Panhandle gas field by a geologic dip or fault, and ownership lay with only a few large landowners making gas rights negotiations relatively easy.

Negotiations soon began for government ownership of the gas rights to the 50,000-acre field in the interest of national defense. Although rights were secured for most of the field in a short period of time, negotiations over rights to the entire structure dragged on until well into the 1930s. Meanwhile, the government bought 18 acres seven miles west of Amarillo for the new helium extraction plant site. Groundbreaking took place in August of 1928, a pipeline was built from the Cliffside field eleven miles to the north, and the plant began operations in April of 1929 with the first refined batch of helium shipped a month later on May 6.

The United States quickly became the producer of 90% of the world’s supply of helium and the advent of WWII in the 1940s greatly increased demand for the product. Shipping helium at 2,500 psi was a problem from the beginning, when it was either shipped by specially designed rail cars or in small specially designed tanks. By the early 1950s, Jack B. Kelley of Amarillo who had been transporting some of the very small tanks as cargo developed a unique tank truck that could safely transport the gas using tanker trucks. Over the next 30 years or so his firm was essentially the only company in the nation capable of hauling exotic gases at extremely high pressures.

By the early 1960s the Cliffside structure, after 30 years of production, was becoming partially depleted. As a result, the Helium Acts Amendment of 1960 (Public law 86-777) was enacted in order for the Bureau of Mines to allow private plants to be built for the extraction of helium from natural gas. That law resulted in the building of five helium extraction facilities within the largest region of helium rich gas fields that roughly encompassed portions of southern Kansas as well as the panhandles of Texas and Oklahoma. Included in that region are the gas fields of Hugoton, Keyes, Greenwood, and Panhandle. Additionally, the Bureau of Mines approved a 425-mile pipeline beginning near Bushton, Kansas, to the Cliffside facility at Amarillo to act as a gathering system for the new extraction plants. The raw helium produced by those plants is transported by the pipeline and injected into the Cliffside structure for storage until it can be extracted and refined to a pure helium state.

By 1995 more than a billion cubic meters of raw helium had been stored in the reserve, although the operation had created a debt of $1.4 billion for the project. As a result the U.S. Congress in 1996 passed the Helium Privatization Act of 1996 (Public Law 104-273), which directed the U.S. Department of the Interior to empty the reserve. Sales to the government and government contractors only opened in 1998 and sales on the open market began in 2003. The process paid off the program indebtedness and sales have continued from the reserve to the present.

Although the Cliffside helium extraction facility, with its service to a huge region, has been by far the largest project of its kind in the United States, there are several other smaller facilities in the nation. Among those are isolated gas fields in Arizona, Colorado, Utah, and Wyoming, where for the most part helium is in the five to six percent range and the gas is not associated with hydrocarbons as it is in the original discoveries. Thus far oil and gas operators in the Permian Basin have not produced wells capable of helium production, but with all the changing technology and enhanced capabilities of the industry who knows what the future holds.

Bobby Weaver is a regular contributor to PboilAndGasMagazine.com. His humor column, “Oil Patch Tales,” is a regular feature in the print edition.