By John de Viet, Solutions Development and Sales Support Manager at KROHNE

With the skyrocketing cost of fuel, the impacts of any mistakes made while loading and unloading liquid natural gas (LNG) carriers is increasing. This makes it even more important for plant and instrumentation managers to have access to the most accurate measurement tools. New automated systems provide transparency in measuring fuel quantity and quality, improving trust between buyer and seller. These new tools can reduce maintenance costs by as much as 25-50 percent annually and can also avoid costly disputes at terminals, estimated at between $1-10 million per year.

Loading and unloading of liquid natural gas (LNG) carriers requires documentation of both the quantity and quality of the LNG transferred. As per gas sales purchase agreement (GSPA), this information, recorded in a quality certificate, and a bill of lading, is usually derived from multiple instruments and independently operated systems. Plant managers have typically used manual data collection, calculation, and verification systems to obtain the required information.

Quantity is typically determined with level measurements taken on the LNG vessel; these measurements are the input for the bill of lading. Quality is determined in a laboratory using samples collected during the (un)loading operation, with the results used to prepare the quality certificate. Data is manually processed primarily in Excel-based worksheets, without traceable references to instrument uncertainties and standards and with no dynamic validation.

Accurate calculations have been made even more complicated by the fact that LNG is a mixture of gas and liquid. Unlike transfer standards for oil or gas, which are well-defined and well known, those for LNG are less advanced. Many operators have had to rely on collecting information from independent systems doing just a portion of the measurements, with no one fully integrated measurement system. The existing manual quantity and quality data collection systems have led to a variety of potential problems:

- Introduction of human error during data collection.

- Certificates of quality are produced using distributed control system (DCS) historians or external plant information systems, including the PI real-time data management software and MS Excel. None of these systems are designed and dedicated for custody transfer applications.

- Data is transferred through multiple interfaces with the possible loss of resolution or loss of data due to filtering (ISO demands up to 6th decimal point).

- Calculations have not been validated or certified by an independent body such as NMi,

- Quality data is not traceable, and measurements are often not in compliance with ISO/GPA standards.

- There is no dynamic validation of data while LNG loading is in progress.

- Validation of data is often done after the shipload, with no way of reconciling if equipment had developed faults during the loading.

- Contractual clauses differ, which could lead to incorrect interpretations and calculations.

- Overall loading system is difficult for authorities to audit.

New Automated Systems Eliminate Uncertainty Disputes

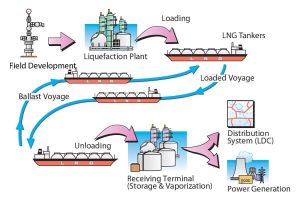

New automated systems are now available that eliminate uncertainty disputes, reduce maintenance costs, and make loading and unloading of LNG carriers at terminals easier and more efficient. Among these is the KROHNE LNG-Quality Release System (L-QRS), a software offering that collects all relevant information needed to determine the amount of energy transferred during LNG vessel loading and unloading operations. See accompanying chart for a graphic overview of typical loading/unloading points in the LNG value chain.