When you’re at the duty-free shop at Tokyo International Airport and you see a bottle of Jack Daniels you know one thing: the only place in the whole world it comes from is Lynchburg, Tennessee. This is the kind of pride one can take when surveying the fact that more of the Permian’s needed infrastructure and manufacturing is happening in the Basin itself. One does not need to be an industrialist or keep up with the news to see what is happening. “Every time I drive into Midland for hitch from East Texas I see more and more facilities being built,” observes Luis Raymundo, Lead Chemical Operator at Refined Completions.

Manufacturing, Mergers, and the Permian Basin

The Permian Basin has long been the epicenter of America’s energy production, with drilling and extraction occupying the forefront of the Basin’s activity, but over time a robust manufacturing sector has emerged as a critical pillar of the region’s economy. Companies like Odessa Separator Inc. (OSI) and Affinity Steel exemplify the growth and innovation taking place. Meanwhile, recent mergers and acquisitions (M&A) among oil and gas giants have reshaped the industry, bringing greater efficiency, operational improvements, and economies of scale. These factors, combined with an evolving political and economic landscape, position the Permian Basin for sustained growth in the years ahead.

The Rise of Advanced Manufacturing in the Permian Basin

Odessa, located within the Permian Basin, is rapidly becoming a center for advanced manufacturing. The city’s well-established energy industry has led to a surge in demand for manufacturing suppliers. Access to raw materials like carbon, oil, and sand reduces production costs and accelerates manufacturing processes. The availability of land and financial incentives further contribute to Odessa’s appeal for manufacturing growth.

Manufacturing in the Permian Basin has steadily increased over the years, evolving to meet the demands of an expanding energy sector. Companies like Odessa Separator and Affinity Steel have capitalized on this growth, expanding their operations and adopting advanced technologies to stay ahead of industry needs.

As one of the leading manufacturing companies in the region, Odessa Separator has spent the past 25 years enhancing its manufacturing profile. According to CEO Gustavo Gonzalez, OSI has significantly reorganized its production floor and adopted new technologies to boost efficiency.

“The company has consistently implemented new processes and reorganized its manufacturing floor to enhance efficiency,” Gonzales said. “Currently, OSI operates approximately 64 machines, including CNC lathes, mills, plasma tables, saws, welding stations, and pull test equipment. The addition of welding and CNC robots has further automated multiple operations, reflecting OSI’s commitment to continuous improvement.”

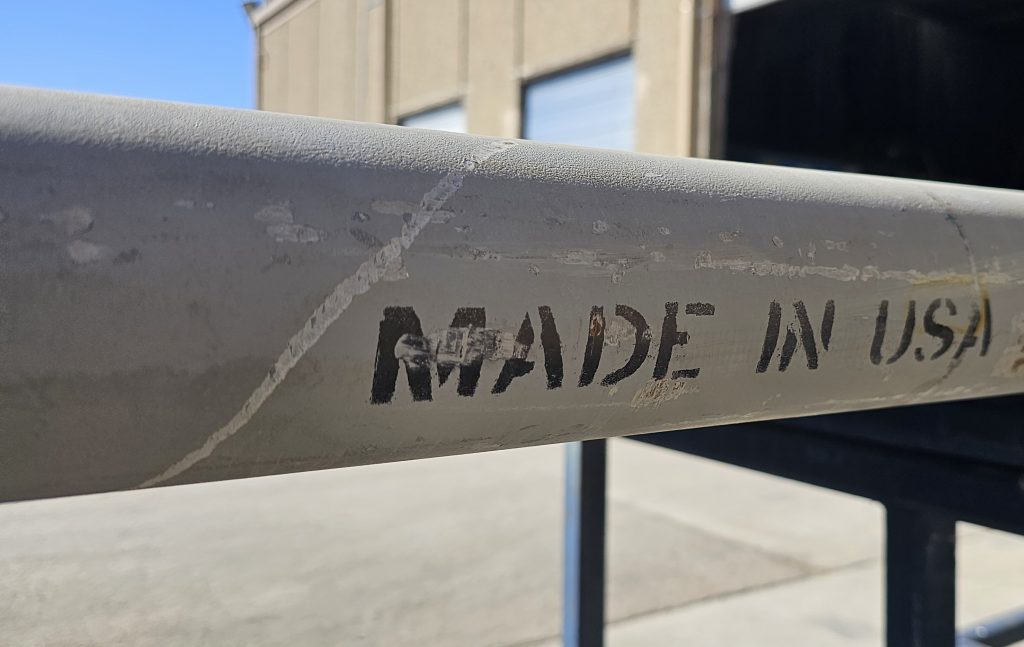

OSI’s ability to manufacture in-house, close to its customer base, provides a significant advantage over suppliers that rely on imported raw materials and components. Many larger competitors ship materials overseas for manufacturing before transporting them back to the Permian Basin—a months-long process. By contrast, OSI’s centralized operations allow for shorter feedback loops, faster product improvements, and closer collaboration between engineers, chemists, and machinists.

Recently I toured OSI’s manufacturing facility in Odessa with Derrick Black, who oversees the firm’s Business Development department. I saw, first hand, AI robots that were programmed in-house to mill and machine parts for their proprietary sand filtration systems. Said Black, “While the technology and methods change, the goal is always the same—maximum production for the longest amount of time.” Indeed. As we weave between CNC machines, lathes, and racks of completed parts, Derrick assures me that things are only getting better, “The future of OSI is the future of the Basin. Things are looking very, very good.”

Brandon Adams, CEO of Affinity Steel, has also witnessed the steady growth of manufacturing in the Basin firsthand. When Affinity Steel opened its first 10,000-square-foot shop, it likely didn’t anticipate needing multiple expansions. However, demand has surged alongside the region’s continued development, which led to the construction of a new 100,000-square-foot facility in May 2024.

Affinity Steel specializes in providing structural steel and buildings for operators of all sizes. The company has played a key role in shaping the Basin’s infrastructure, partnering with major industry players, such as Fasken Oil and Ranch and Tanner Services, to deliver high-quality manufacturing solutions. The company’s expansion reflects broader industry trends—manufacturers in the Permian are producing more than ever, including new products, such as chemical pump enclosures to support oilfield operations.

But it doesn’t stop there. ChampionX has completed a multi-million-dollar project to upgrade its chemical manufacturing hub in Odessa. Since 1975, this plant has been pivotal for oil and gas, particularly in developing production, completions, and midstream chemistries. The recent enhancements include state-of-the-art automation and packaging technologies, such as an automated tote and drum filling station. These improvements aim to meet increasing industry demands while reducing inter-plant transportation and associated carbon emissions by approximately 56.7 tons of CO₂ annually. Additionally, ChampionX has expanded its workforce, bringing the total number of full-time employees at the site to 68. The efforts have yielded lower transportation emissions and cost, and more local employment. Moving manufacturing to the Permian Basin should be a no-brainer.

“There are less booms and busts and more diversification across the Basin. While oil will always dominate the local economy, things have smoothed out like a shaved cactus,” says Dusty Roach, former safety manager and current host of *The West Texas Slant* podcast. A San Angelo native, who now lives in Midland, Roach is recently retired from working in Odessa. With over 40 years in oil and gas, he knows what he’s seeing. The growing presence of manufacturing helps stabilize the region’s economy, providing jobs and reducing dependency on outside suppliers.

Mergers, Acquisitions, and Industry Consolidation

Alongside the rise of manufacturing, the oil and gas sector in the Permian Basin has undergone a wave of mergers and acquisitions, fundamentally reshaping the landscape. The acquisition of Pioneer Natural Resources by ExxonMobil in May 2024 for $60 billion positioned Exxon as the largest shale producer in the Permian. The deal is expected to drive earnings growth and increase free cash flow, validating the financial advantages of consolidation.

Similarly, Permian Resources’ 2023 acquisition of Earthstone Energy resulted in production outperformance and improved operational efficiency, while Diversified Energy’s $1.3 billion purchase of Maverick Natural Resources in 2025 expanded its footprint in the Basin. This latter move is projected to boost revenue by 95 percent and free cash flow by 55 percent, underscoring the strategic benefits of scale.

In September 2024, Delek Logistics Partners LP completed a $230 million acquisition of H2O Midstream. This move positions Delek as a full-service midstream leader in the Permian Basin, enhancing its capabilities in water handling and infrastructure within the region.

Midstream operators are rapidly building out natural gas processing capacity in the Permian Basin to accommodate anticipated production growth. For instance, Brazos Midstream has expanded into the Midland Basin, reflecting the industry’s proactive approach to addressing potential bottlenecks and ensuring efficient processing of natural gas.

As companies merge and consolidate assets, they gain greater negotiating power, enhance supply chain efficiencies, and streamline operations. The Permian’s midstream operators have also ramped up natural gas processing capacity to accommodate growing production, reducing bottlenecks and optimizing resource extraction.

The Political and Economic Future of the Permian Basin

With the election of President Donald Trump, the political climate appears favorable for domestic oil and gas production. Policies promoting energy independence and reduced regulatory burdens could benefit companies like OSI and Affinity Steel that prioritize U.S.-based manufacturing.

“For OSI, focusing on domestic production aligns well with national policies, which could enhance its competitive position. However, it is essential to stay vigilant and adaptable to changing economic conditions in order to effectively capitalize on these opportunities. We aim to continue expanding our opportunities in the Permian,” Gonzalez notes.

As the region continues to evolve, the interplay between manufacturing growth, industry consolidation, and political shifts will shape the future of the Permian Basin. The combination of advanced manufacturing, strategic M&A activity, and a favorable policy environment positions the region for long-term stability and success.

Sources: Odessa American, Odessatex.com, oilgasleads.com, spglobal.com, bulktransfertx.com

https://www.odessatex.com/why-odessa/target-industries/advanced-manufacturing/

Christian Lombardini, a former field operator and manager, is now a communications and content consultant for oil & gas companies and creators. You can find Christian and his The Oilfield Leader Podcast on LinkedIn.