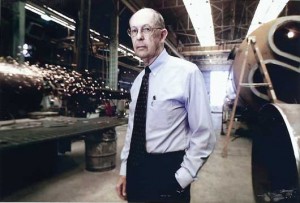

Dick Sivalls’ roots in the oil and gas business run more than a century deep.

“My grandfather started a company similar to ours in 1900 in Ohio and then moved to Bartlesville and Oklahoma City, following the oil patch,” he said. “He sold the business, but then my father started the business in 1947 in Odessa, and I took over in 1974.”

Sivalls, Inc., designs, manufactures and sells oil and gas production equipment worldwide.

“Everything between the wellhead and the pipeline,” explained Sivalls, listing tanks, treaters, separators, gas production units, heaters, water knockouts, dehydration units, water treating equipment, gas treating equipment, and emission control technology among the myriad types of oil and gas production equipment that his company designs and manufactures in Odessa.

Sivalls also has manufacturing facilities in Brownwood and Pampa, Texas, as well as in Casper, Wyo., and the company maintains sales and service offices in Houston; Oklahoma City; Hobbs, N.M.; Bernal, Utah; Casper and Evanston, Wyoming; and Williston, N.D.

Mike George, president and CEO of the Odessa Chamber of Commerce, calls Dick Sivalls “one of the brightest stars in the Permian Basin’s business sky.”

“Ever since taking over the reins of Sivalls in 1960, as its third-generation owner/operator, Dick has provided the company with visionary leadership,” George said. “Dick, along with his extremely loyal team of business associates, has grown Sivalls into a worldwide-respected manufacturer of oil and gas production equipment. Dick and his wife Lura are major contributors to the arts community and numerous organizations working to improve the quality of life in the Permian Basin.

“One of Dick’s strongest leadership skills is his patience in his decision-making process,” George added. “Dick will gather the facts on both sides of an issue, before he responds. Consequently, when he finally speaks, people listen.”

Paul Kenworthy, of Kenworthy Oil, is an Odessa-based oil and gas professional who has known Sivalls for many years. Kenworthy describes Sivalls as a great contributor to the city and its culture, as well as a civic leader who has done tremendous good not just in Odessa but across the Permian Basin.

“If you’ve got a hard job—he’s the one to give it to,” Kenworthy said. “And if you’re talking about job creation—if you’re talking about skilled and semi-skilled workers, about welders and engineers and occupations like that—then Sivalls Inc. and the companies they control are employers who have created a huge amount of jobs, great jobs, for many years in the Permian Basin. They’ve been here and never left. Their stuff is so good it is exported to Russia. So all these things that [political candidates] talk about, about how to get us out of the mess we’ve seen with unemployment, trade deficits, etc., well, that’s Sivalls Inc. They’ve done it, and for years.”

For his own part, Sivalls, when contacted for this article, admitted to being involved in long days and even-higher-than-normal activity, due to the current boom.

“It is hard to comprehend what is happening in the Bakken Shale oil play in North Dakota,” he said. “We think we have a boom right now in the Permian Basin, but we don’t know what a boom is. I just heard today that McDonald’s in Williston is paying $20 an hour to work behind the counter. Raw recruits in the oil field are making $18 to $20 an hour. There are people making $80,000 to $100,000 a year who are living in their cars because they can’t find a place to live.”

He said Sivalls, Inc., previously bought a shuttered manufacturing facility in Casper, Wyo., that it is bringing back on line because “we can’t stay up with the equipment in the Rockies.”

Sivalls said he was amazed when the industry figured out how to produce natural gas in the Barnett Shale using horizontal drilling and hydraulic fracturing. The industry is now carrying that technology into tight sands and shale oil and gas plays all around the country, according to Sivalls.

“Of course, no one knows how long these wells will last,” he offered, “but they are making a bunch of oil and gas.”

The new technology being used in the industry today has caused Sivalls, Inc., to redesign some of its equipment. For example, Sivalls said operators are drilling eight wells from one location in the Rockies, bending the drill bit in various directions.

“Because of that, we are building equipment that can handle four to eight wells,” he stated. “We are combining what we were already doing, only bigger and more complicated. They have done that offshore for years, but now they are doing it on land. It has changed the technology of what we are doing.”

Sivalls said his company, which sells nearly half of its equipment internationally, has done “one-third to half of its business in Russia for the last 15 years.”

“We have been doing large equipment in Russia for years,” he explained. “They combine a lot of production equipment in one location because they don’t have to worry about paying royalties. The government owns it all.”

Although dealing with the Russian government can be a challenge contractually at times, according to Sivalls, it has been good so far because the company uses an international line of credit.

“In some ways, it is very good,” he claimed. “When we get a design, they repeat it over and over, so we do a lot of repeat business, which is good.”

All of the equipment Sivalls, Inc., sends to Russia is manufactured in Odessa.

“It is built in Odessa,” he said. “We break it down, truck it to Houston, put it on a ship to St. Petersburg and then put it on the Trans Siberian Express railroad to the middle of Russia. We can have it on location in 60 days. The weather is so bad over there they don’t want to be tromping around in the snow. It is like a little gas plant with lots of computer controls. That way they can sit in a nice warm control room. So we are now building our own computers and programs.”

In addition to its manufacturing business, Sivalls, Inc., owns a supply store called Control Equipment, Inc., which he said is the exclusive dealer of oilfield valves and controls. It has stores in Odessa, Lubbock, Pampa, Wichita Falls, and Cleburne.

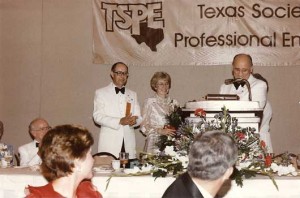

Sivalls was recently honored as the recipient of the 2011 National Philanthropy Day Outstanding Philanthropist award from the Permian Basin Chapter of the Association of Fundraising Professionals.

“I was surprised and humbled,” he responded. “It was a nice honor. I never considered myself a high roller as far as giving, but Lura and I try to help everybody we can.”

Sivalls has been active over the years with the United Way, the University of Texas-Permian Basin, the Midland/Odessa Symphony, the Art Institute, and the Salvation Army, just to name a few of the organizations that have been recipients of Sivalls’ charitable contributions.

Sivalls and his wife have two children, a son Tracy and a daughter Stephanie

Latimer, who are both involved in the family business, making them the fourth generation working for Sivalls, Inc.

So what does his crystal ball predict for 2012?

“We just want to keep on growing,” Sivalls emphasized. “We had a heck of year in 2011, better than we expected.

We had good domestic and international sales. I see nothing but good for our industry unless some bad edicts come out of Washington. In the Permian Basin, water may hold up the fracking more than anything else because of the drought, unless they figure out how to use brine water. But they are. There are a lot of smart people, and they will figure that out. There is such energy demand that the U.S. may become a net exporter. As long as there is political unrest in the Middle East that keeps the price up, people will keep going after the hard-to-get stuff because they can get a return on their investment.”

And as long as the industry continues to drill to meet the world’s increasing energy demands, the production equipment that Sivalls, Inc., manufactures will be needed. Sivalls currently employs approximately 250, including its Control Equipment supply stores.

“We have the manufacturing capacity that we could double our production with a second shift, but we need people,” he stated. “We are currently working a single shift, but we are working long hours, 55-58 hours a week.”

All of the company’s equipment is built domestically so they can control the quality, according to Sivalls.

by Al Pickett, special contributor