Click here to listen to the Audio verison of this story!

“Information is a source of learning. But unless it is organized, processed, and available to the right people in a format for decision making, it is a burden, not a benefit.” —C. William Pollard, author and former CEO of ServiceMaster (1938-2025)

“Knowledge is power,” said Sir Francis Bacon in 1597, but 400 years ago he wasn’t dealing with the firehose nature of data collection in today’s sensor-jammed oil patch. Pollard’s caveat involving organization, processing, and formatting is what keeps the ship afloat in today’s data flood.

Oilfield service companies like Emerson, Sensia, and others are bringing new technologies designed to manage and leverage that data.

Permian Progress

Adin Nand, based in Houston, is Emerson’s Director of Business Development globally, specifically focused on the company’s DeltaV SaaS SCADA (Software-as-a-Service) platform. That and Emerson’s edge computing technology are working together to quickly gather information, interpret data, and advise action on oilfield operations.

Permian Progress

Nand sees the Permian as a world leader in the energy industry’s move to adopt new technology, especially in new production. “Anything greenfield is coming out highly technologically advanced,” Nand observed. “We’re talking about new drills, new facilities, new critical infrastructure like pipelines. It is absolutely cutting edge.”

And while legacy assets may still be mostly connected to older systems, even there some operators are seeing a positive return on investment (ROI) by upgrading their technology in order to maximize efficiency, extend production, meet environmental standards, and reduce non-productive time (NPT), Nand said.

With Permian production possibly leveling off this year for the first time in about two decades—excepting the COVID-19 anomaly in 2020—many are seeing the need for upgrading legacy assets to improve productivity and efficiency.

Nand explained, “DeltaV SaaS SCADA is a cloud-based software-as-a-service industrial control system. It’s been very popular in the Permian with independent companies.” Many majors have the finances to create and manage their own in-house systems, while independents and medium to smaller firms benefit from contracting out such services to a company that specializes in SCADA systems, he said—although some majors, those with heavily remodeled or exploratory assets are moving toward SaaS as well.

Reduced capital expenses, improved cyber security, and scalability are what Nand sees as the benefits of SaaS and outsourcing in general, including DeltaV.

And today’s economics almost force operators to explore using cloud-based control systems. “If you’re not in the cloud, you’re unsafe from a cyber security perspective, you lack options for environmental sustainability initiatives, and you’re not going to have any path to AI-based production optimization. So, I believe at this point, the transition is a must.”

Giving Producers the Edge

Storing data on the cloud is one thing—and is an important source of historical data backup and security. But when exceptions happen in the field, and every second matters in responding to a problem, the cloud alone is still limited. Delays involved in relaying data across the miles can be costly.

That’s where edge computing shines, said Nand. “The edge device sits locally, having an instantaneous sub-second interaction with your assets. That offers three main benefits.”

The first is data buffering. When data is at home on the range, it doesn’t require costly and time-consuming data links to the cloud. Recording and processing datapoints in sub-second increments through the cloud would overload geographically dispersed communications systems. Buffering it on an edge computer enables on-the-spot evaluation, while aggregated packets of that data can be uploaded to the cloud in wider intervals, such as one minute or five minutes, for backup and storage.

“Cryout” alarming is the second benefit, enabling management by exception. “We are not challenged with having the infrastructure or the resources to have humans in non-critical asset control rooms 24/7 anymore,” Nand pointed out, so systems that monitor for outliers and trends can manage that data without human involvement. Often it can be months between alarms, and that’s a lot of time that humans are not staring at a perfectly normal data stream – they can then be deployed for more important operational matters.

The third benefit “is tied to the whole list of prescriptive and descriptive analytics, with machine learning, artificial intelligence. You can now run those many of these applications on an edge device versus solely in the cloud,” Nand said.

Speed is the key. “The Edge devices execute optimization applications right in the field,” without delays inherent in accessing the cloud.

The cloud is still important, as stated, for data backup and longer term trending. “A cloud control system is turbocharged with an edge device.” Through the cloud they can do longer-term, more advanced analysis such as adjusting ESP or rod pump speeds to maximize both production and mechanical efficiencies.

Combined systems are empowered to make some autonomous decisions, then re-evaluate the move’s success and make more adjustments until an issue is solved, all while notifying humans of the progress.

I’ve Got You in the Palm of My Hand

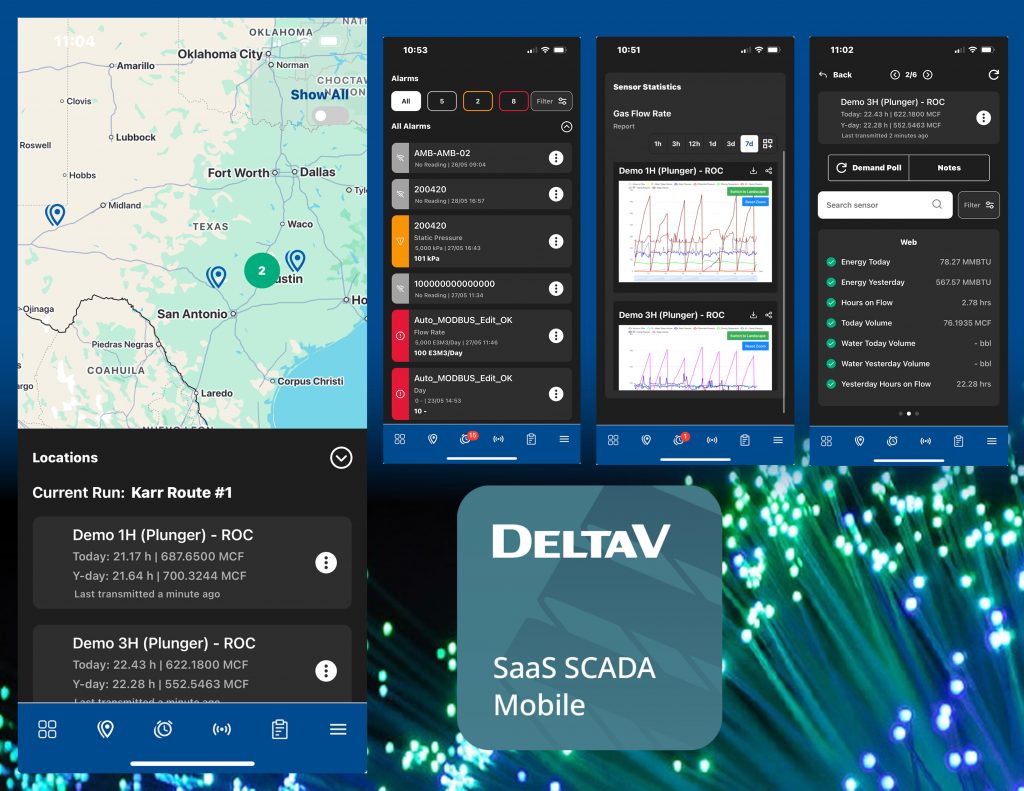

Emerson’s new version of their longtime mobile SCADA app is releasing this summer as DeltaV SaaS SCADA Mobile. The new app is loaded with additional features and filtering abilities with the goal of “putting SCADA in the palm of your hand in the form of a mobile application, which has never been done at this scale before,” said Nand. He added, “You could essentially run a whole field from palm of your hand in an actual mobile application, not just logging into a website on your smartphone’s browser.”

A full-featured mobile phone app fits with the new generation of college graduates entering the workforce who are already checking bank accounts, adjusting home thermostats, and ordering groceries with their smart phones. Information systems like this also intuitively accelerate the process of learning decades of operational history and knowledge for new staff, whether they’re just out of college or coming from another company. This can shorten the learning curve.

In Oilfield Data Management, the Exceptions Rule

Continuing the theme of flexibility and adapting to change is Sensia’s Avalon system, designed to be equipment and cloud agnostic and, like DeltaV, to adapt to the constant changes inherent in oilfield operations.

Houston-based Sensia, LLC is a joint venture created by Rockwell Automation and SLB (formerly Schlumberger) in 2019. Pal Roach, senior principal industry consultant, oil and gas for Rockwell, said Sensia is “the world’s largest enterprise focused solely on delivering oil and gas automation and digitalization, I think clocking in at more than 1,100 employees at numerous offices around the world.”

The product in view is called Avalon. Roach described it as “a real-time scalable cloud platform” that is “specifically designed for on-site data collection from well pads, unconventional production, traditional production, terminals, pipelines, etc.”

An open platform, Avalon is designed to be vendor and cloud neutral. That’s important for any producer that is starting, upgrading, or aggregating data collection in the field, Roach said. “You don’t need to deal with multiple data platforms, licenses, service agreements or technology roadmaps that can create challenges upfront and over time.”

That’s especially good for an operator aggregating properties gained from merger and acquisition (M&A) activity, where the newly acquired assets may already have deployed several vendors and iterations of hardware within those vendors—and replacing all of that would be time-consuming and budget-busting.

In Roach’s view, making the platform open is the only way to go. “It’s got to be open. It’s got to be vendor neutral, and it’s got to be cloud agnostic. There’s enough barriers and prerequisites and all the other solutions out there, this doesn’t add any more to that. Everything is open.”

The promise of this openness is that it meshes with existing databases, software, and reporting systems as well. Roach said the company takes care of assimilating everything upon installing the system.

Avalon is an upgrade over a previous offering known as connected production, something that had its roots in the Permian Basin, he pointed out.

Better Data, Better Results

Avalon’s uses include oil production facilities, pipelines, terminals, and energy transition facilities. In those uses, it can aggregate data from a long list of data collection devices including but not limited to sensors, RTUs, controllers, edge and intelligent devices, and more.

For a producer that has begun by simply collecting data, Roach said that is a great start. But there’s much more to be gained by processing the data and making it talk sense, as Avalon does. It provides context and visualization, along with analytics that can suggest appropriate solutions and actions when issues arise—including real-time control over assets.

He added, “You can customize applications in the platform and Sensia is growing a library of preconfigured applications for you to pick from. It’s sort of like an app store.”

Among the growing list of Avalon apps are a lift surveillance one that is “a suite of lift application that provides intelligent surveillance in a single platform/single pane of glass: AI Response Prioritization (AIRP) for ESPs (a big step toward autonomous lift, single-view workflow that can assess/interpret thousands of alarms per minute and prioritize those few that require immediate action); Automated Gas Lift Optimization (automated well adjustments based on real-time conditions that can respond in minutes without manual intervention),” among others, said Roach.

Among its benefits are that Avalon can improve production rates, boost resource recovery, reduce operating overhead, and reduce downtime.

Road to Autonomous?

Currently, Roach said, “Platforms like Avalon help you work on the right things at the right time.” Some of that comes from training personnel to ask AI the right questions to get the right answers. Also, “You need the humans to test whether it gave the right answer.”

A properly intuitive system can help people in other departments understand the operation. Rockwell has a class of applications called “connected workforce” where someone who is a field worker or instrument tech who can access data to do their own job better.

And while most of these apps are designed for use in the control room, Roach said field workers can see pump trends from a tablet.

AI is No Longer Optional, It’s Operational

In full agreement with the necessity of AI and full-on data gathering is a Novi Labs survey released this summer, in which they surveyed more than 150 U.S. based reservoir engineers.

They found that “Organizations with established analytics teams grew from 19 percent to 28 percent, while another 28 percent are actively building these capabilities. Combined, 56 percent of the industry now has dedicated AI resources, up from just 41 percent last year. Companies aren’t just buying software; they’re hiring data scientists and restructuring entire operations.”

And, as Nand and Roach recommended, they’ve moved away from custom-only development (declining from 35 percent to 22 percent), “toward proven hybrid approaches that blend commercial solutions with targeted customization (increasing from 38 percent to 53 percent). These hybrid approaches consistently deliver the highest success rates at 72 percent, proving that balanced strategies outperform extremes.”

They’re also seeing the benefit of collecting their own data, said the report. With inaccurate public data, surveyed engineers found that AI only magnified the mistakes (remember the “garbage in, garbage out” mantra of the 1970s? It still applies).

So, they’re taking it into their own hands. “But here’s what’s really changing: who owns the problem. Seventy-four percent of reservoir engineers now say they’re primarily responsible for data quality, up from 65 percent. The industry is shifting data governance away from IT departments and toward the people who actually suffer when the data is wrong.”

Humans Needed

The need for humans will always be there, Nand declared. While some fear a loss of jobs through the efficiencies of AI, “What you need to be aware of instead is that those who don’t adopt technology may be replaced by people who have adopted it.” However, he assured, “They’ll never be replaced by technology. You need that human touch to manage it properly.”

A longtime contributor to PB Oil and Gas Magazine, Paul Wiseman is an energy industry freelance writer.