Fresh offerings of products and services for the oil and gas set.

You Load 60 Tons? What Do You Get?

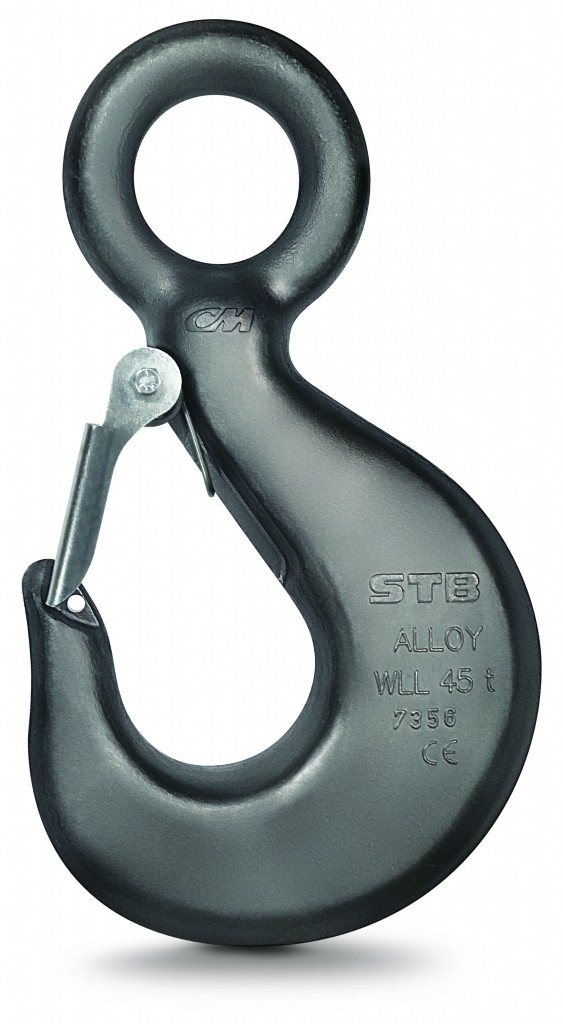

You get this hook. Expanding its line of high-quality, forged rigging hooks, Columbus McKinnon Corporation (NASDAQ:CMCO), a leading designer, manufacturer and marketer of material handling products, now offers high-capacity rigging hooks with capacities ranging from 31‐1/2 to 60 tons.

These competitively priced hooks are well suited for heavy‐duty lifting applications, with features such as:

5:1 design factor–the same design factor as wire rope, so there is no need to downgrade

Ultra‐strong, forged latch tab, pre‐drilled for easy latch installation

Quenched and tempered material to deliver maximum strength with minimal unit weight and size

Highly visible load rating marking for easy identification to help ensure safe and proper use

In addition to high‐capacity hooks, Columbus McKinnon also offers rigging hooks in capacities ranging from 3/4 to 15 tons. All CM rigging hooks are machined and heat treated in the U.S.A. For more information, call Columbus McKinnon Channel Services at 800‐888‐0985 or www.cmworks.com.

About Columbus McKinnon

Columbus McKinnon is a leading worldwide designer, manufacturer and marketer of material handling products, systems, and services, which efficiently and ergonomically move, lift, position, and secure materials. Key products include hoists, cranes, actuators, and rigging tools. The company is focused on commercial and industrial applications that require the safety and quality provided by its superior design and engineering know‐how. For more information on Columbus McKinnon, visit www.cmworks.com.

***

Detect Asphaltenes in Oil Production

A new ASTM International standard will help to more quickly and accurately detect for contaminants called asphaltenes in a variety of petroleum products. The new standard (soon to be published as D7996, Test Method for Measuring Visible Spectrum of Asphaltenes in Heavy Fuel Oils and Crude Oils by Spectroscopy in a Microfluidic Platform) will thus improve efficiency in producing crude and heavy fuel oils. D7996 is ASTM’s first microfluidic-related standard.

According to ASTM member Farshid Mostowfi, Ph.D., asphaltene deposits in the oil production process cost the industry billions of dollars annually. “The asphaltene problem exists deep in reservoirs, along transportation networks, in refineries and all the way in fuel systems,” says Mostowfi, a principal scientist and program manager at Schlumberger. “Therefore, monitoring asphaltenes and their variations is paramount to avoiding expensive remedial operations.”

Measuring asphaltene deposits has traditionally required bulky glassware, well-ventilated laboratory environments, and skilled operators. These techniques take up to two days to perform.

The new standard will cover gasoil, diesel fuel, fuel oils, residual fuel oils, lubricating oil, and bitumen, as well as crude oil that uses microfluidics and spectrographic techniques.

To purchase standards, visit www.astm.org and search by the standard designation, or contact ASTM Customer Relations (tel +1.877.909.ASTM; sales@astm.org). ASTM welcomes participation in the development of its standards. One can become a member by visiting www.astm.org/JOIN.

For more ASTM news, visit www.astm.org/sn-energy.

***

OPW Engineered Systems Adds New Rack Monitor

OPW Engineered Systems, part of OPW’s Fluid segment within Dover Corporation (NYSE:DOV), has added the RM140W Rack Monitor to its line of terminal solution offerings. Built for truck or rail loading in petro-chemical applications, the RM140W protects against overfills and continuously monitors the grounding connection, increasing safety at the point of transfer.

“The RM140W is going to make it easier for loading operators to get the job done safer and faster,” said Dave Morrow, Director of Products for Engineered Systems. “Its electrical system is approved for use in North America and Europe, it can handle almost any probe, and automatically adjusts for 2-wire and 5-wire systems. The RM140W is the ultimate rack monitor.”

In addition to being universally compatible, the RM140W meets or exceeds the requirements of multiple organizations as an explosion-proof device.

The RM140W Rack Monitor replaces the Opti-Therm 8500 Series, and is available now. For ordering information, or to schedule a product demonstration, please contact OPW Engineered Systems. To download information on the RM140W, or view the order guide, visit RM140W’s product page.

For more on OPW Engineered Systems, visit www.opw-es.com.

***