Fresh offerings of products and services for the oil and gas set.

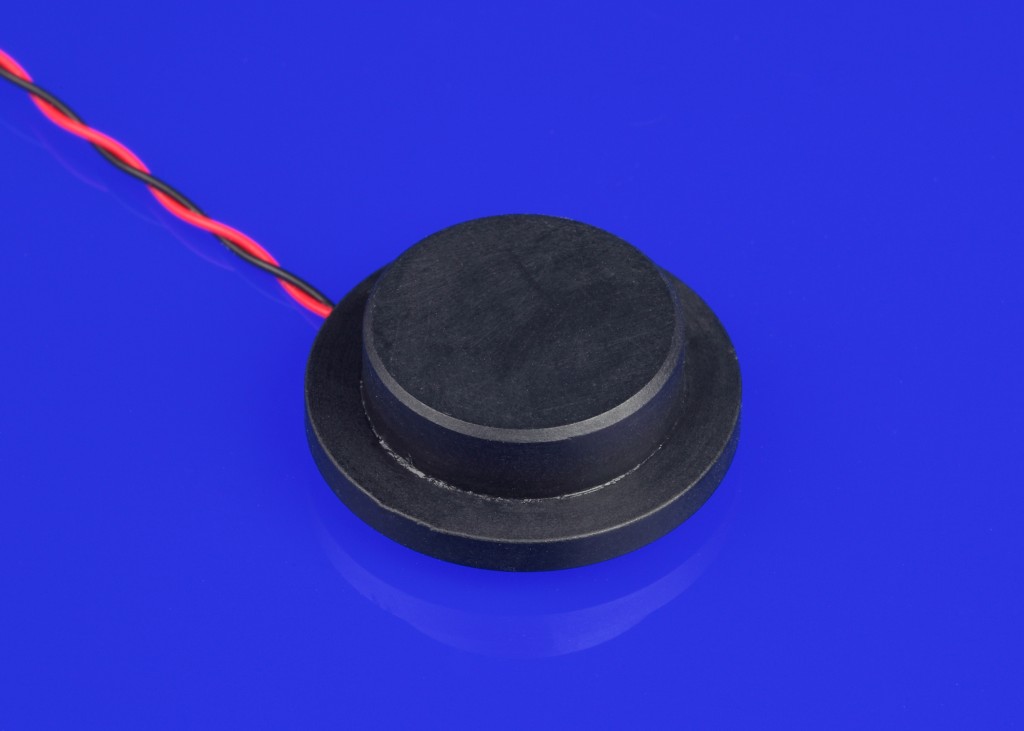

Push-In Foam Earplug

Honeywell (NYSE:HON), on Apr. 6, announced the Howard Leight TrustFit Pod push-in foam earplug that provides workers with properly fitting ear plugs to protect against noise-induced hearing loss (NIHL).

Research shows that half of all industrial workers experience progressive, long-term hearing loss—in part because many struggle to fit their earplugs for proper hearing protection. The new Howard Leight TrustFit Pod earplug from Honeywell is designed with an ergonomic stem and dimpled foam tip so they are easy to fully insert and remove without picking up dirt from a worker’s fingers. They are comfortable to wear throughout the workday.

Features include:

Ease: The Howard Leight signature soft foam with dimpled tip collapses to be easily and gently pushed into the ear without the need to roll down, helping to reduce hygiene concerns and time-consuming insertion.

Comfort: The ergonomically contoured paddle fits naturally between the finger and thumb, even when wearing lightweight work gloves. Its flexible stem material gently pushes the dimpled foam into the narrowing ear canal to rest comfortably throughout the workday.

Trustworthy: The patent-pending TrustFit Pod earplug design was developed using the Howard Leight VeriPRO earplug fit-test system to reliably measure fit consistency.

TrustFit Pod push-in foam earplugs provide effective NRR 28 dB, Canada Class A(L) hearing protection. The earplugs are available in both uncorded and corded versions, and may be cleaned and reused in accordance with user instructions.

To request a free sample, visit http://www.honeywellsafety.com/trustfit.

TrustFit Pod push-in foam earplugs are immediately available from industrial safety distributors in the United States and Canada. For more information, visit http://www.honeywellsafety.com/trustfit.

About Honeywell

Honeywell (www.honeywell.com) is a Fortune 100 diversified technology and manufacturing leader, serving customers worldwide with aerospace products and services; control technologies for buildings, homes, and industry; turbochargers; and performance materials. For more news and information on Honeywell, please visit www.honeywellnow.com.

About Honeywell Industrial Safety

Honeywell Industrial Safety (HIS), part of Honeywell Automation and Control Solutions, provides comprehensive solutions to help organizations manage workplace safety in an increasingly complex world. HIS helps organizations with connected, real-time safety intelligence to respond to safety threats, manage risk to the business and improve productivity. In addition to offering the broadest range of industrial safety products—from personal protection gear for a worker’s eyes, ears and heads, to fall protection harnesses and respiratory protection, software, first responder gear, and toxic gas monitors—HIS helps organizations make better decisions by connecting sensors throughout customers’ operations to deliver an accurate picture of safety at all times.

Gas Flow Measurement

Morgan Advanced Materials, an industry-leading specialist in the design and manufacture of sensing technology solutions, now has the capability to develop gas flow transducers, which remain accurate when subjected to extreme temperatures and the presence of highly corrosive chemicals.

Drawing on its extensive knowledge and experience in gas, transducer technology used within a range of applications, Morgan has surpassed industry standards by producing sensors that are operational within an even greater range of temperature extremes than ever before. For instance, its latest gas flow transducers can now work within a temperature range of -50ºC to 250ºC (-58°F and 482°F). This greater tolerance to extreme temperatures and harsh environments, i.e. those likely to experience variances in gas flow, makes Morgan tranducers ideal for use within oil and gas exploration as well as bulk gas meters for industrial applications. In addition, Morgan’s capability within very low temperature sensing means that it has been able to test and measure the flow of cryogenic fluids down to -175°C (-283°F).

These developments will enable Morgan to respond to a growing market demand for compact sensors that remain extremely accurate, to within 0.1 percent, irrespective of harsh environmental conditions. Morgan’s selection of materials are both extremely thermally stable and resistant to corrosion, enabling transducers to operate under high temperature as well as in the presence of aggressive gaseous acids. Perhaps more significant, however, is Morgan’s groundbreaking work in minimizing zero-flow offset, which ensures a superb level of calibrating transducers accordingly in response to fluctuations in temperature. Within the next few months, this capability will enable Morgan to deliver standard solutions for the wider industrial market or, indeed, for any other application where there is a requirement to accurately measure large quantities of high-temperature fluids or gas.

Charles Dowling, of Morgan Advanced Materials, commented, “This enhanced capability will enable us to better serve our customer base by ensuring we can provide solutions to meet all requirements. In addition to a standard range of gas transducers that are currently in the pipeline, the possibility of designing custom solutions for niche applications, in a range of materials, is now very much a reality. By continuing to push the boundaries, we aim to support our customers in overcoming their most pressing engineering challenges.”

Leak Detection Technology In Pipeline

Telvent Canada Ltd. (“Schneider Electric”) and IntelliView Technologies Inc. (“IntelliView”), on Apr. 5, announced their agreement to collaborate and deliver IntelliView’s video analytics-based leak-detection technology as an integrated offer in the Schneider Electric Enterprise Pipeline Management System (ePLMS) applications suite, specifically within the OASyS DNA SCADA system platform. The agreement is effective immediately.

“As part of Schneider Electric’s strategy in delivering state of the art solutions for safe pipeline operations, including advanced leak detection technologies, our agreement with IntelliView will allow us to offer comprehensive below-and-above-ground embedded solutions with improved identification of small leaks in above ground facilities,” says Larry Stack, senior vice president, Schneider Electric, “We are committed to delivering integrated solutions for pipeline management from the field assets to the enterprise. Our continuous investment keeps us the most trusted control room solution provider in the industry, managing more than 60 percent of the hydrocarbon movements in North & Latin America.”

“We are delighted that Schneider Electric has chosen IntelliView’s video analytic leak detection system to complement their industry-leading suite of safe pipeline operation applications for liquids pipeline operators,” says IntelliView’s Executive Chairman, Bill Hews. “We have worked closely with lead customers in a very demanding and critical environment to apply advanced analytics on video and thermal output to provide reliable, low-threshold and real-time leak detection. This agreement will accelerate the application of this new toolset in the industry.”

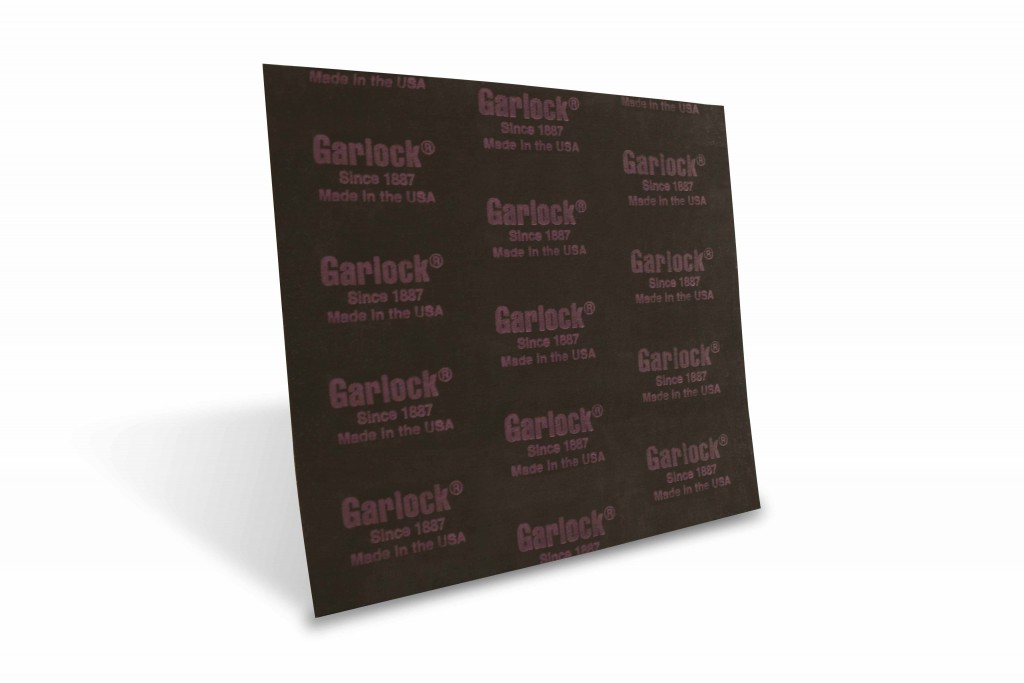

Fluoroelastomer Rubber Sheet

Garlock, a leading manufacturer of high-performance fluid sealing and pipeline protection products, on Apr. 7, introduces its new Style 9938 rubber sheet material for use in chemical, oil & gas, and other applications that require a 100 percent fluoroelastomer material.

Due to its resistance to acids, aliphatic and aromatic hydrocarbons, fuels and ozone, 100 percent fluoroelastomer material is often specified in many general service industrial applications. Heater treaters, one of the key applications for this product, subject gaskets and sealing materials to a range of aggressive chemicals.

“Style 9938 is designed to be a cost-effective, utility-grade solution for applications that require a 100 percent fluoroelastomer sealing product,” Garlock’s Sr. Product Manager Bruce Stratton said. “While this product will meet many industrial requirements, our applications engineers are available to consult with our customers to determine the appropriate material for their specific needs.”

Garlock offers Style 9938 in full-roll sheets, or cut into discrete gaskets to customer specifications. The rest of the product line, including Style 9520 and Style 9518, satisfies even more stringent requirements in terms of harshness and resistance to chemical attack.

Style 9938 can be specified:

- Where resistance to acids, aliphatic & aromatic hydrocarbons, fuels, and ozone is required.

- When cost is an issue but a 100 percent fluoroelastomer rubber sheet is required.

- Where high temperature seal-ability and compression set requirements are moderate.

Scada Software

In the new Version 7.4 of the Simatic WinCC Scada software, Siemens is focusing on greater efficiency and openness. Furthermore, Simatic WinCC can now also be used with Windows 10 Professional and Enterprise. The WebUX option for the web-based operator control and monitoring using commercially available HTML5-compatible devices via the Internet has been considerably extended in its functionality. WebUX now supports all popular WinCC controls and enables objects to be made more dynamic by means of script. For the purpose of greater openness, the channel to the Simatic S7 controllers has been extended and is now also enabled, for example, for large plants with up to128 S7-1500 controllers. In addition, a standard OPC UA client has been integrated in order to exchange data easily with third-party systems. For the exchange of data (iDoc) with MES (Manufacturing Execution System) and SAP systems, the WinCC IndustrialDataBridge option has been extended to include an XML file-based interface.

Various functional expansions in Simatic WinCC Version V 7.4 increase the engineering efficiency. The user is supported, for example, by a drag and drop facility between Configuration Studio and Graphics Designer as well as extended search and replace functions. Furthermore, bulk data can be processed purposefully in Version V 7.4 by means of a VBA (Visual Basic for Applications) interface. At runtime bar charts are now supported, and the trend and the bar chart control has been expanded to include intuitive multi-touch gesture control, zooming and panning. For the efficient diagnosis of Simatic S7 controllers the system diagnosis control is now available.