Fresh offerings of products and services for the oil and gas set.

Free Electronic Field Ticket

Phoenix DAS has introduced a free version of their mobile electronic field ticketing application. The free OpenTicket module allows service companies to replace paper-based field tickets, enhancing workflow in the field, improving the accuracy of information, and decreasing the payment cycle from customers.

The OpenTicket module is fully mobile, works in both online and offline modes, and includes a live dashboard for tracking completed, in-progress and invoiced jobs. Management teams are provided with full visibility of each job, and can follow every step in real time. Companies that are using the OpenTicket module have reported a reduction in days’ sales outstanding of 12-15 days, on average, as compared to paper-based tickets.

The OpenTicket module can be used standalone, or combined with other Phoenix DAS software modules depending on a company’s needs and challenges.

For additional information, visit www.phoenixdas.com/openticket.

Mobile Clear Technology

AMGAS Services Inc. (AMGAS), a full service Hydrogen Sulfide (H2S) and emissions treatment company, was invited to the 2016 SelectUSA investment summit to assist in bringing safe, innovative, and cost-effective solutions to the American market.

Oil and gas producers in the United States are experiencing firsthand the challenges of producing resources laden with Hydrogen Sulfide (H2S) and dealing with associated site emissions. Working in this environment, companies must account for the increased risks to the safety of workers and corroding equipment in their project operating costs. Product recovery and venting during well operations can have a significant impact on the environment and are difficult to manage when H2S is present. AMGAS Services Inc., a world leader in emission control has created innovative ways to safely handle and process H2S specific to the challenges of the US market.

“H2S is very dangerous, so the processes used must be beyond dependable,” says Steve Martinson, General Manager of AMGAS Services Inc. “For AMGAS, innovation has always meant that our patented chemicals, processes, and equipment have been thoroughly tested and proven reliable.”

With dramatic increases in shale and unconventional resource production across the United States, access to and use of fresh water is becoming more and more difficult. This is especially true in areas where water disposal and fresh water restrictions have increased significantly over the last few years.

“AMGAS designed the Clear process to provide a chemical-free way to treat sour oil in certain applications, however the process has really taken hold in areas where treating sour water is just as important,” says Sheldon McKee, director of business and product development for AMGAS. “Clear has shown it can reduce disposal and operational costs by as much as 50 percent.”

The AMGAS Clear system can be used to sweeten produced water for re-use in well servicing and production applications. By reusing produced water, the AMGAS Clear system reduces the amount of water being disposed of and eliminates the need for fresh water use. In addition to water treatment, the Clear process provides tremendous value in oil treatment applications. By removing H2S from crude oil, the AMGAS Clear system provides operators a greater degree of flexibility and increases economic opportunities, as improved oil quality allows market access to sweet crude oil pipelines and terminals.

“Clear really is about making your sour products sweet,” McKee says, “more opportunities to control the environmental impact on site and more opportunities to sell better, sweeter oil to the market.”

Recently, AMGAS launched the Mobile Clear system, which incorporates the sweetening technology and trucking all in one system. This mobile system allows the Clear system to reach individual or smaller producing wells while delivering the best economic return for the producer.

Mobile Clear joins a suite of product and services that AMGAS has successfully deployed in the largest markets around the world. Products like SCOR (Sour Crude Oil Recovery), Ready Service for Plant Shutdowns and Turnarounds, or ACT (AMGAS Capture Technology), designed to mitigate the dangers of BTEX (Benzene, Toluene, Ethylbenzene, and Xylenes) and hydrocarbon emissions. Each of these technologies developed in concert with industry, aimed at reducing operational costs, safeguarding the environment, and most importantly, protecting workers. More information on Mobile Clear is available at http://clear.am-gas.com

About AMGAS Services Inc.

AMGAS is a Canadian corporation and has been a world leader in H2S treatment since the late 1980s, with offices across Western Canada, the United States, and in the Middle East. Safely handling H2S requires trained experts using dependable and innovative equipment, chemicals, and processes. AMGAS developed specialized services fitting the specific needs of their different locations, operating at the intersection of chemicals, equipment, and service. AMGAS takes pride in working closely with their clients to ensure safety on site and provide expert assistance for all H2S treatments. For more information, please visit www.am-gas.com.

The Future of Water Transfer

Select Energy Services, LLC (Select) recently announced the launch of AquaLogic, a full suite of automated water transfer solutions. AquaLogic consists of automated equipment, including pumps and a proportioning system, that responds to operator specifications and changing conditions in real time.

“This is essentially the next step to enhancing efficiency in water operations,” said Nate Banda, director of operational technology for Seley. “AquaView gives our customers the ability to monitor and track their water; Aqualogic allows them to automate the movement of water and conduct operations closer to their physical limits while maintaining strict safety standards.”Select Energy Services, LLC (Select) recently announced the launch of AquaLogic, a full suite of automated water transfer solutions. AquaLogic consists of automated equipment, including pumps and a proportioning system, that responds to operator specifications and changing conditions in real time.

| AquaLogic water transfer pumps use sensors and programming to operate and maintain desired water flow rates by modulating pressure within the system. The pumps remotely and automatically transfer water by raising and lowering pump RPM based on incoming and discharge water data points that are collected and shared throughout the system.

“We now have the ability to remotely set and maintain operational parameters,” said Michael Skarke, vice president of water solutions for Select. “When this system detects that a certain threshold has been crossed it’s going to alert the operator; but at the same time, the automated system is going to take intelligent action to keep operations running safely and smoothly. This includes raising a pump’s RPM to maintain desired flow rates, or shutting down the system and valves completely in the event of a failure. That’s the power of AquaLogic.” |

The second element of the AquaLogic suite is the proportioning system, which consists of a large manifold equipped with a programmable logic controller (PLC) and various sensors. With the proportioning system, operators can combine two fluid streams, such as produced water, heavy brine, flowback water, and freshwater to extend the life of water sources and reduce dependence on salt-water disposal wells. AquaLogic combines both streams based on operator specifications and can maintain flow rates up to 100 barrels per minute.

Incorporating impaired water into completion operations allows energy producers to save money and time spent trucking water to and from worksites. In addition, the remote, self-monitoring system increases personnel utilization while also reducing costs and the chances of human error or recordable safety incidents.

“Aqualogic is a game changer for energy producers who want to manager water safely, quickly, and cost effectively,” said John Schmitz, chief executive officer for Select. “This level of efficiency and safety is the key to prolonging E&P operations in this market. Select is committed to being the leader in developing cutting edge technology that delivers precision, value, and convenience to our industry.”

AquaLogic allows for the collection and communication of precise information to allow Select’s clients to make informed decisions concerning engine output, water flow, and water storage requirements. It directly integrates with AquaView, the company’s suite of real time water asset monitoring technology.

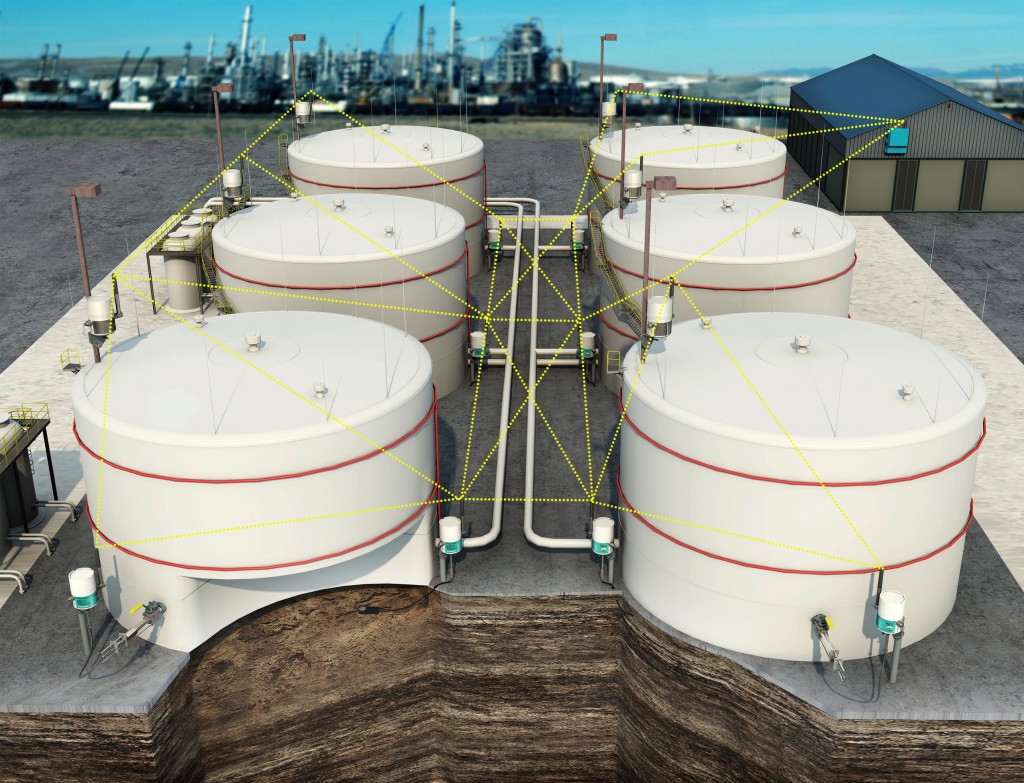

Wireless Transmitter for Tank Corrosion Monitoring

The new Cosasco ER 300 Series Wireless Transmitter allows for an easy, affordable upgrade of oil, fuel, or chemical storage tank corrosion monitors to fully automated data collection systems.

Corrosion in oil, fuel, and chemical storage tanks occurs both internally, from corrosive water gathering in the bottom of the tank, and externally, from water seeping under the tank floor. Typically located in tank farms near suburban or environmentally sensitive areas, leakage of a tank’s contents caused by corrosion could have a disastrous impact on local ecosystems. To ensure the effectiveness of anti-corrosion treatment systems, storage tanks require both internal and external corrosion monitoring. Older tank farms often have inadequate monitoring systems with no integrated data management, limiting data quality and access.

The ER 300 transmitter uses WirelessHART7 and ISA 100 Wireless communication to allow easy integration with existing protocols, with no cabling costs. When installed, the transmitter can collect data from multiple monitors across a tank farm to create a comprehensive monitoring system that ensures the integrity of storage tanks. Wireless communication removes the need to visit the site to record data, saving travel time, and providing the most up-to-date corrosion data.

A new application note on wireless corrosion monitoring for tank farms is available for download at www.cosasco.com/marketing/Tank_Farms_CM.pdf. More information can be found at www.cosasco.com.

Industrial Rack PC

The Simatic IPC547G industrial PC from Siemens extends the company’s range of industry-standard rack PCs in the 19″ format. The powerful new IPC with high processing power and excellent system and data availability is particularly suitable for compact industrial workstations and servers, where it is used for fast parallel processing of large volumes of data. The range of applications extends from high-end image processing, process visualization and SCADA (Supervisory Control and Data Acquisition) systems, to industrial servers/workstations as well as test stands and manufacturing-level data management systems. The Simatic IPC547G is equipped with a higher level of access protection as well as the latest PC technology, such as Intel Xeon and Intel Core-i processors of the 6th generation, as well as DDR4 RAM of up to 64 GB. The enclosure concept for the new rack PC has also been further developed and is now easier to service, expand, and maintain allowing it to win the “Red Dot Award 2016” for product design.

The new enclosure concept of the Simatic IPC547G rack PC is designed for easy access to components making expansion, maintenance, and service quicker. For example, the enclosure cover can be opened with a single screw while fans, filter mats, or hard discs can be replaced without the need for tools in a slide-in changing unit. Front-panel LEDs and the Simatic IPC DiagBase/DiagMonitor diagnostics software also support preventive maintenance and rapid troubleshooting.

Simatic IPC547G offers a high level of system and data availability and reliable 24/7 operation under harsh ambient conditions, including temperatures up to 40 degrees Celsius. System availability is also improved by a redundant power supply unit (hot-swap) and the secure remote access via the Intel iAMT 11.0-aided Simatic IPC RemoteManager. Versatile RAID1/5 configurations—with HDDs, SSDs or an optional hot-spare hard drive – are available to ensure a high level of data availability.

Up to five monitors can be connected to the versatile new Simatic IPC547G with its flexible expansion options. Additional monitors offer greater usability and a better overview, for example, in complex SCADA applications. System expansion is possible thanks to five PCI express and two PCI slots as well as PCI express 3.0 and USB 3.0 ports. Two of the USB interfaces can be protected against unauthorized access by the lockable front door.

The new Simatic IPC547G rack PC is available in freely scalable configuration, as well as in off-the-shelf versions with a short delivery time. The required Windows 7, 10 IoT Enterprise or Server 2008 R2/2012 R2 operating systems are pre-installed and activated. Siemens offers a wide range of certifications for global use of the new unit in industrial applications, as well as dependable long-term availability and worldwide service and support.

Monitoring From Keytroller

Countless companies are faced with the real and often costly predicament of how to monitor and track the location of their equipment in remote jobsites. Solving this issue, Keytroller, a designer, manufacturer, and supplier of electronic safety and weighing devices, has unveiled the CYBERWATCH SAT—a satellite wireless hour, alarm, and location meter designed for remote locations.

Machinery is heavily used in remote locations like mines, logging sites, drilling rigs, off-shore oil rigs, and international ships. These applications typically don’t have cellular or Wi-Fi connectivity and monitoring their usage is expensive and troublesome. Tackling these dilemmas, the CYBERWATCH SAT provides equipment monitoring from anywhere in the world, without the need for a SIM card or local wireless plan—at less than $40 per month.

CYBERWATCH SAT utilizes the Iridium network and transmits up to six-hour meter readings and six alarm readings with GPS location, once per day. This data can then be viewed in the client’s own web portal or have the data sent to a smartphone where it can be exported via DropBox for further manipulation and viewing.

Aside from monitoring data, this clever device can also be used as a hub communicator. An operator can wirelessly connect his/her smart phone to the device mounted on a piece of equipment. Once connected, the operator can send an email or text message from their smartphone through the SAT device to anywhere in the world—a potentially lifesaving feature.

If a user has the CYBERWATCH SAT’S phone number, they can also text a command to that number. When the command is received, the device will respond with the hour meter, alarm, and location data back to the phone that made the inquiry.

Free demo kits are available for qualified users by contacting Keytroller at (813) 877-4500.

About Keytroller, LLC:

Founded in 1988, Keytroller, LLC designs, manufactures, and supplies a full line of electronic safety devices designed for forklifts, construction equipment, aerial lifts, personal carriers, boats, and vehicles. Their solutions include: RFID/code, access-monitoring systems; electronic checklist automation; impact and speed sensing and control; directional shift controls; anti-theft wireless relay systems; digital video DVR recorders with GPS; wireless camera viewing systems, forklift spotlight warning LED, cellular and Wi-Fi hour meters; and high accuracy hydraulic weigh scales.

Keytroller is headquartered in Tampa, Fla., and enjoys relationships with over 500 North American equipment dealers (aftermarket) many OEM vehicle manufacturers (installed as original equipment) and importers in England, Europe, Australia, South America, and Southeast Asia. Visit www.keytroller.com for more information.