Fresh offerings of products and services for the oil and gas set.

Next-Generation Acoustic Analysis Service

Halliburton announced on Sept. 20 the release of the Acoustic Conformance Xaminer service (ACX), a technology to help operators identify and pinpoint costly wellbore leaks by analyzing sound waves that describe flow patterns in the formation and casing.

The service employs an array of hydrophones that measure sound in and around the wellbore. Based on the measurements and analysis, this service has the ability to determine which annulus or completions system is leaking in real-time. Unlike other ultrasonic detection technologies, the ACX service stores high-definition data internally, which can be downloaded at surface and sent to the Halliburton Formation and Reservoir Solutions (FRS) group for advanced processing.

This data allows engineers to develop 2D flow illustrations to further characterize the leak, reducing uncertainties. The ACX service saves time by providing a continuous mode to quickly identify areas with possible leaks in the wellbore. It can also take stationary measurements to refine areas where leaks are identified by monitoring activity. In some cases, this enables more precise flow rate and phase estimations at leak locations.

“We designed the ACX service to be part of a full suite of diagnostic services and to be combined with production logging and cement evaluation instruments,” said David Topping, vice president of wireline and perforating. “By providing operators with greater insight and improved capabilities, we help facilitate greater returns from their reservoirs.”

Recently, an Alaskan oil company deployed the service to a well with a gas lift completion that could not be gas lifted due to a leak. The ACX service clearly identified the depth and spatial position of the leak near the casing hanger. As a result, a sealant option was identified as the optimal solution, allowing the operator to avoid a more complex intervention saving millions of dollars in workover costs.

The subsurface manager said, “The new ACX technology will be invaluable to our organization to find small tubing or casing leaks that we were not previously able to locate. To know definitively where the leak is provides us with the best opportunity to perform a repair. Being located in Alaska, our costs are extremely high, so reducing the amount of time to diagnose and repair leaks has a large value to us.”

The ACX service can be utilized in a variety of environments, including mature fields and unconventionals.

About Halliburton:

Founded in 1919, Halliburton is one of the world’s largest providers of products and services to the energy industry. With over 50,000 employees representing 140 nationalities, and operations in approximately 70 countries, the company serves the upstream oil and gas industry throughout the lifecycle of the reservoir—from locating hydrocarbons and managing geological data, to drilling and formation evaluation, to well construction, completion, and production optimization. For more information, visit the company’s website at www.halliburton.com.

Wellbore Shielding and Stabilization

Impact Fluid Solutions, a premier provider of specialty additives for oil and gas drilling, cementing, and completions, announced on Sept. 26, the expansion of its FLC line of wellbore shielding and stabilization solutions. A series of new FLC products will build on the success of Impact’s industry-leading FLC 2000 additive for drilling fluids, while offering broader capabilities to meet specific well parameters and requirements.

Designed for depleted and mechanically weak formations, FLC additives act as shielding agents, forming a tough, impermeable barrier at the fluid-rock interface. This shield minimizes fluid and pressure invasion, stabilizing and strengthening the wellbore.

For over a decade, leading operators, oilfield service providers, and fluid companies have trusted Impact’s FLC 2000 to reduce non-productive time, preserve wellbore integrity, and improve ultimate recoveries in basins worldwide. Compatible with water-, oil- and synthetic-based fluid systems, FLC 2000 seals fractures up to 250 μm.

The newest FLC additives are specifically designed for today’s oil and gas environment, as operators are challenged to reduce well costs and improve production. The expanded FLC product line will help operators succeed in a wide variety of difficult drilling conditions by offering increased capabilities to provide fit-for-purpose solutions.

“FLC 2000 has enabled our customers to prevent fluid loss, formation damage and lost circulation incidents in over 3,000 wells around the world,” said Rod Uchytil, president and CEO of Impact. “However, every drilling program is different. This exciting expansion of our FLC product line will enable our customers to solve a broader range of wellbore stability challenges while optimizing mud weight and solids in the fluid system.”

In addition to FLC 2000, the expanded FLC product line includes:

- FLC Fine—Seals fractures up to 150 μm while the smaller particle size improves solids control management, reducing maintenance costs without compromising performance.

- FLC Supreme—Seals 500 μm fractures with a broad sealing range that does not require bypassing the shale shaker systems.

- FLC Extreme—Seals 500-3,000 μm fractures at high differential pressures, offering a comprehensive range of sealing capabilities while still allowing the continuous use of shale shaker systems.

- FLC Max—Seals 250 μm fractures; engineered specifically for oil- and synthetic-based fluid systems, with enhanced lipophilic properties to accelerate sealing, reduce HPHT fluid loss and spurt loss, improve oil phase dispersibility and reduce maintenance costs.

About Impact Fluid Solutions:

Impact (impact-fluids.com) is a premier fluid solutions provider to oil and gas operators, service companies and fluid companies worldwide. The Impact team combines advanced chemistry with extensive oilfield expertise to deliver products purpose-built to solve real and complex wellbore challenges. The company provides best-in-class additives for drilling, cementing and completions, including Impact’s flagship FLC 2000 for wellbore shielding and stabilization. Proven in basins worldwide, Impact is trusted by industry leaders and smaller independents alike to improve performance, predictability and—ultimately—production.

Versatile LED Floodlights

The new 6125 series (for zone 1) and 6525 series (for zone 2) floodlights from R. STAHL are designed for challenging environments such as chemical flood, and oil and gas extraction. Offering a service life of 50,000 hours, they feature high corrosion resistance supported by a robust IP66/67-rated enclosure.

Energy-efficient LED technology makes R. STAHL’s new generation of flexible floodlights for hazardous areas shine. High-quality TIR lenses minimize scattered light and glare effects and enable light distribution focused on angles of 10, 40, or 120 degrees.

The devices are therefore not only suitable for spot and wide-angle lighting, but can even be installed as pendant lights. The new 6125 series (for zone 1) and 6525 series (for zone 2) floodlights achieve exvellent luminous flux. 21,000 lm in versions with 210 W power consumption and 12,00 lm in 120 W models. With this luminaire efficiency of 100 lm/W, they are not only far more efficient than conventional HID lights, but also require significantly less maintenance. The lens panel modules are equipped with hinges for easy installation, maintenance, and repair of the removable components. Even under extreme conditions, the service life of these products is specified at 50,000 hours of operation at maximum ambient temperatures. Their superior durability fully enables them to sustain challenging environments e.g. in the chemical industry or in oil and gas extraction over the long term. Their high tolerance for ambient temperatures in a very broad range from -40 degrees to 60 degrees Celsius is a stand-out feature in this product class. Featuring a corrosion-resistant body and comparably low weight, these floodlights are an especially good choice for onshore and offshore applications. Special designs with heat sinks made from sea-water-resistant aluminum are also available.

For some application such as general lighting in production and storage facilities in the food industry, they can be ordered with a scatter protection for the glass front panel. The robust enclosures provide IP66/67 ingress protection and a very high shock and impact resistance (IK10). They are available either in powder-coated steel sheet or stainless steel versions. For explosion protection expert R. STAHL, these new floodlights are the final complement to a now comprehensive portfolio of highly efficient LED lighting solutions.

- STAHL presents further information about this new series, LED technology in general, and real-life experiences with explosion-proof luminaires in harsh conditions at www.stahl-explorers.com.

Open Hole Stimulation 30 Times Faster than Plug-and-Perf Method

Packers Plus Energy Services Inc. recently announced an operator successfully stimulated a StackFRAC HD open-hole multi-stage ball-drop system in Argentina’s Loma La Lata field. This field-proven, cost-effective completion technology effectively stimulates multiple stages thereby increasing access to the reservoir, and resulted in a stimulation time which was 30 times faster than that of the traditional plug-and-perf method. Open hole completions have been proven to increase induced fracture complexity and provide superior connection to the reservoir.

“The operator wanted a completion system that was more time efficient, as well as a system that would avoid proppant overdisplacement and its negative effect on production, whilst lowering operational risk,” said Packers Plus President, Ian Bryant. “We’re very pleased to have delivered on both counts and look forward to continuing to optimize completions for operators in the region.”

The completion, which would have taken an estimated 220 hours using the coiled tubing plug-and-perf technique (assuming a smooth operation), was successfully completed in 7 hours with the StackFRAC HD system, averaging one stage per hour. This saved the operator approximately $280,000 (US).The frac spread utilization rate was 85 percent of total completion time. Because the StackFRAC system uses a continuous pumping operation and does not require trips between stages, the operator was able to control fluid placement, avoiding proppant overdisplacement, and avoid the potential risk associated with multiple coiled tubing runs. Additional time and cost savings were achieved with the use of degradable balls, which mitigated the need for post-stimulation intervention.

The key to successful multistage stimulation is connecting to a complex fracture network, maximizing near wellbore conductivity and reducing pressure drops during production. To date, Packers Plus has successfully completed more open-hole wells than any other service company in Argentina. To learn more about Packers Plus’ proven performance and international experience, visit packersplus.com/proven-performance.

About Packers Plus:

Packers Plus is an industry leader in designing and manufacturing lower completions solutions for a variety of technically challenging applications. Known for its innovative, high-quality and responsive style, the privately held company has run over 16,000 completion systems, accounting for over 240,000 fracture stages since it started operations in 2000. Today, Packers Plus has employees around the world, maintaining an influential role in key markets and remaining true to its roots. For more information, visit more at packersplus.com.

Parker Releases New Air Driven Liquid Pump

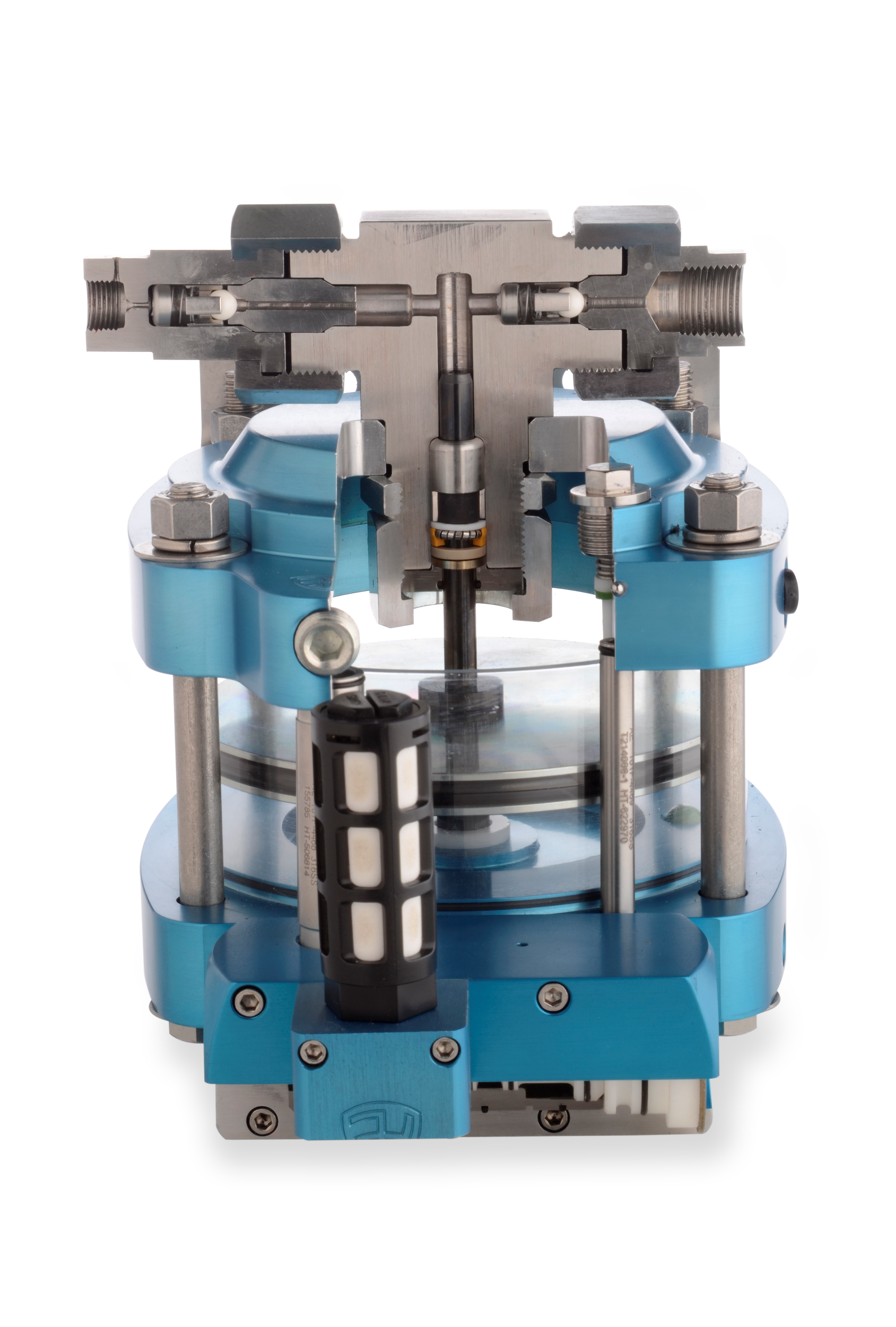

Parker Autoclave Engineers, part of Parker Hannifin—the global leader in motion and control technologies, has released an innovative new air driven liquid pump, the AHL118.

A high-volume, double-ended, double acting high pressure pump, the AHL118 is designed for use in oil and gas, chemical, industrial, and research applications.

The pump operates to a pressure range of 23,000 psi and at 5.6 gallons per minute (25.5 litres). The AHL118 is designed to be extremely robust, featuring a carbon-based prioritised coating to the plunger, which is three times harder than Stellite. This makes the plunger unscratchable, extending the lifespan of the seals and reducing downtime, repairs, and servicing, delivering major savings to the customer.

All AHL118’s hydraulic parts are manufactured from stainless steel, making them very durable with extended Mean Time Between Maintenance (MTBM) and increasing safety. All AHL118’s pump hardware is manufactured from stainless steel, which is anodized to the bottom and top caps for superior corrosion resistance.

Shawn P. Landry, IPD product manager of pumps/systems for Parker Autoclave Engineers, said, “This air-driven liquid pump offers unrivalled performance and reliability, bringing huge benefits to customers. When developing the product, we analysed what the issues were in the market and so designed a pump that would last significantly longer, lowering downtime and maximizing efficiency.”

Parker Autoclave Engineers has over 70 years’ experience in manufacturing air-driven, high-pressure liquid pumps, valves, and fittings for a wide range of markets. The company offers a comprehensive range of products, with a wide choice of sizes, flow capabilities, output pressures, and additional features. The company’s products are used in a variety of different industries and applications, including hydrostatic/burst/leak, chemical injection, valve/gauge/hose testing, bolt tensioning, hydraulic control systems, laboratory research and autofrettage systems.

Parker Autoclave Engineers combines high pressure industry knowledge, manufacturing expertise, and technological innovation to offer a broad range of products and services to customers across a wide range of industries. This includes low-pressure instrumentation products from 15,000 psi to air driven liquid pumps and packaged systems up to 60,000 psi.

About Parker Hannifin Corporation:

With annual sales of approximately $13 billion in fiscal year 2015, Parker Hannifin is the world’s leading diversified manufacturer of motion and control technologies and systems, providing precision-engineered solutions for a wide variety of mobile, industrial, and aerospace markets. The company employs approximately 55,000 people in 50 countries around the world. Parker has increased its annual dividends paid to shareholders for 59 consecutive fiscal years, among the top five longest-running dividend-increase records in the S&P 500 index. For more information, visit the company’s website at www.parker.com, or its investor information website at www.phstock.com.

The Relio-1 Computer

The newest member of the Relio family of embedded I/O servers, the Relio R1, is redefining “extended.” With an impressive operating temperature range of -40 to +71 degrees Celsius, the rugged, DIN Rail compatible industrial computer is designed to exceed military standards for shock and vibration. This solid-state, zero-maintenance system is ideal for heavy equipment, automation, and other applications that demand powerful processing and a compact footprint.

Mounting options allow secure installation to 35mm DIN Rail located inside panels, vehicles and even heavy equipment and drilling rigs. The rugged, extruded enclosure makes the system ideal for harsh industrial environments.

Product Highlights:

- Choice of single, dual, or quad-core Atom (Bay Trail) processor

- Up to 8GB of DDR3L RAM

- (2) Gigabit Ethernet portsUSB 3.0 port, (3) USB 2.0 high-retention portsSoftware-configurable, two-wire RS-232 or RS-485 serial ports

- DisplayPort, DVI-D, HDMI, and VGA display options available

- Mini PCI Express full-length slot for optional CAN Bus, Wireless, or GPS expansion

- CFast SATA II card slot for solid-state storage and operating system installation

- 18-36 VDC operation

- Wide -40 to +71 degrees Celsius operating temperature range

- Exceeds MIL-STD-810F shock and vibration specifications

- Compatible with Windows or Linux operating systems

- DIN Rail Compatible

The Relio R1 offers your choice of single, dual, or quad-core Intel Atom Bay Trail processor with up to 8 GB of DDR3L low-voltage RAM. Standard I/O features include two software-configurable serial ports, dual Gigabit Ethernet, four high-retention USB ports, and choice of digital and analog display options. The USB ports feature Sealevel’s innovative SeaLATCH locking USB connectors that prevent accidental disconnection of the cables.

The R1 includes the latest CFast SATA II card slot to provide solid-state storage that can be preloaded with Microsoft Windows or Linux operating systems. The system consumes less than 10W and operates from your 18-36 VDC source. Optional CAN Bus 2.0b, wireless dual-band 802.11 b/g/n/ or GPS expansion are also available.

As processor technology evolves, the COM Express design allows the COM module to be upgraded to increase system performance over the life of the application.

The Relio R1 starts at $1,099 and select configurations are available from stock. For more information about the Relio R1, including configuration and display options, visit sealevel.com or call +1 864.843.4343.

About Sealevel Systems, Inc.:

Sealevel Systems, founded in 1986, provides industrial computing solutions in addition to a variety of communications and I/O products including PCI Express and PCI Bus cards, Ethernet serial servers, and USB serial adapters. The product line includes multi-port RS-232, RS-422/485, RS-232/422/485 multi-interface high-speed sync/async, and digital/relay I/O. For more information, visit www.sealevel.com or call 864-843-4343.