Fresh offerings of products and services for the oil and gas set.

Ultra‐Low Headroom Wire Rope Hoist

Expanding its comprehensive line of high‐quality wire rope hoists, Columbus McKinnon Corporation (NASDAQ: CMCO), a leading designer, manufacturer, and marketer of material handling products, systems and services, introduces the Yale LodeKing LT ultra‐low headroom top‐running wire rope hoist. Available in capacities ranging from 10-25 tons, the LodeKing LT is the ideal choice when purchasing a new or replacement hoist for facilities with space limitations.

“Built with 140 years of engineering know-how, the LodeKing family of wire rope hoists combines the latest manufacturing and materials technology with the highest quality components for unsurpassed performance and reliability,” said John Vander Linden, Global Product Manager—Wire Rope Hoists.

Manufactured in Wadesboro, N.C., the LodeKing LT is designed for heavy‐duty CMAA Class D service. Each hoist comes equipped with a Magnetek closed‐loop variable frequency drive that allows for accurate and precise load control while reducing brake wear. Packed with industry‐leading safety and performance features, the Magnetek IMPLUSE VG+ Series 4 drive includes multiple control and power supply options, an external hoist brake resistor, motor thermal overload protection, keypad with digital display, and a recorded fault history that aids in troubleshooting and maintenance.

The LodeKing LT also features plastic‐infused wire rope specifically developed for maximum performance on overhead cranes. This unique wire rope has a plastic core that prevents metal‐to‐metal contact between strands, helping to reduce abrasion and wear within the wire rope, while increasing the rope strength by 15-20 percent.

To learn more about the LodeKing LT or any of the LodeKing wire rope hoists, call Columbus McKinnon Channel Services at 800‐888‐0985 or visit www.cmworks.com.

Model 100 Vertical Grinder

The Eidal Model 100 Vertical Grinder is a stationary grinder powered by a single 100 hp, 460 V, 3-phase electric motor. The grinder shaft is belt-driven by 10 groove v-belt pulleys that spin a 42-1/8” rotor at a speed of 415 rpm. Total weight of approximately 18,000 lbs. with loading hopper. Reduction size can be varied to suit material or end-user without screens or grates through progressive grinding.

The Eidal Model 100 Vertical Grinder can be used for a variety of applications:

- 4 to 6 TPH of wet or dry solid waste

- Wood and dunnage material

- Pallets

- Electronics (e-waste)

- Scrap metal clips, tin cans and non-ferrous metal

- Auto salvage “meatballs” such as alternators, generators, and starters

- Vinyl siding and metal siding

- Milk crates, five gallon buckets and plastics

- Brush and limbs

- Excellent for busting up soil clods.

Flite COV Supplied Air Respirator

The latest model of supplied air respirator features key safety advancements, including an automatic changeover valve for an emergency air supply cylinder (available in different durations) and a locking hand wheel on the cylinder pressure reducing valve to prevent inadvertent shut-off during use. It also features use of the proven compact Tempest Demand Valve, and is compatible with multiple approved Scott Safety facepiece options.

The Flite COV provides safe breathing air supply for many maintenance and safety operations—particularly confined space entry in immediately dangerous to life or death situations—and is ideal for use with a wide selection of Scott Safety products, such as airline trolleys and CEN coupled airline, to provide a complete supplied air system.

Flite COV has been developed to comply with the latest EN 14593-1 and EN 402 approval standards. For further information, please visit www.scottsafety.com/emea.

AC Mitigation PowerTool

Technical Toolboxes, on July 18, announced the release of the new AC Mitigation PowerTool for use by pipeline engineers and technicians. The product now features unlimited pipeline and electric transmission tower line modeling, enabling the user to truly understand and mitigate the underground AC-induced current pipeline integrity problem. The AC Mitigation PowerTool has been developed to assist the engineer or technician to model and mitigate or modify the design of pipeline cathodic protection systems in order to reduce the AC current density effects to meet the criteria specified either by a pipeline owner operator or the National Association of Corrosion Engineers (NACE) standard.

The Pipeline Research Council International (PRCI) AC Predictive and Mitigation software developed by Electro Sciences, Inc. and Dr. John Dabkowski (PRCI Catalog #L51835) has been the de facto industry safety and analysis standard since 1999. The PRCI AC Predictive and Mitigation software was developed to handle multiple pipelines utilizing the same right-of-way with overhead High Voltage (HV) Alternating Current (AC) power lines. A new version of the PRCI field-tested computational engine has been ported to work on current and future “Cloud” and mobile devices as well as the traditional desktop/laptop.

The new AC Mitigation PowerTool can be used from the Cloud or installed on your desktop/laptop. Integration with GPS and Google Earth allows the user to quickly and easily identify the locations, soils, and proximities of the number of pipelines, towers, substations, nodes, crossings, etc. For more information visit www.technicaltoolboxes.com

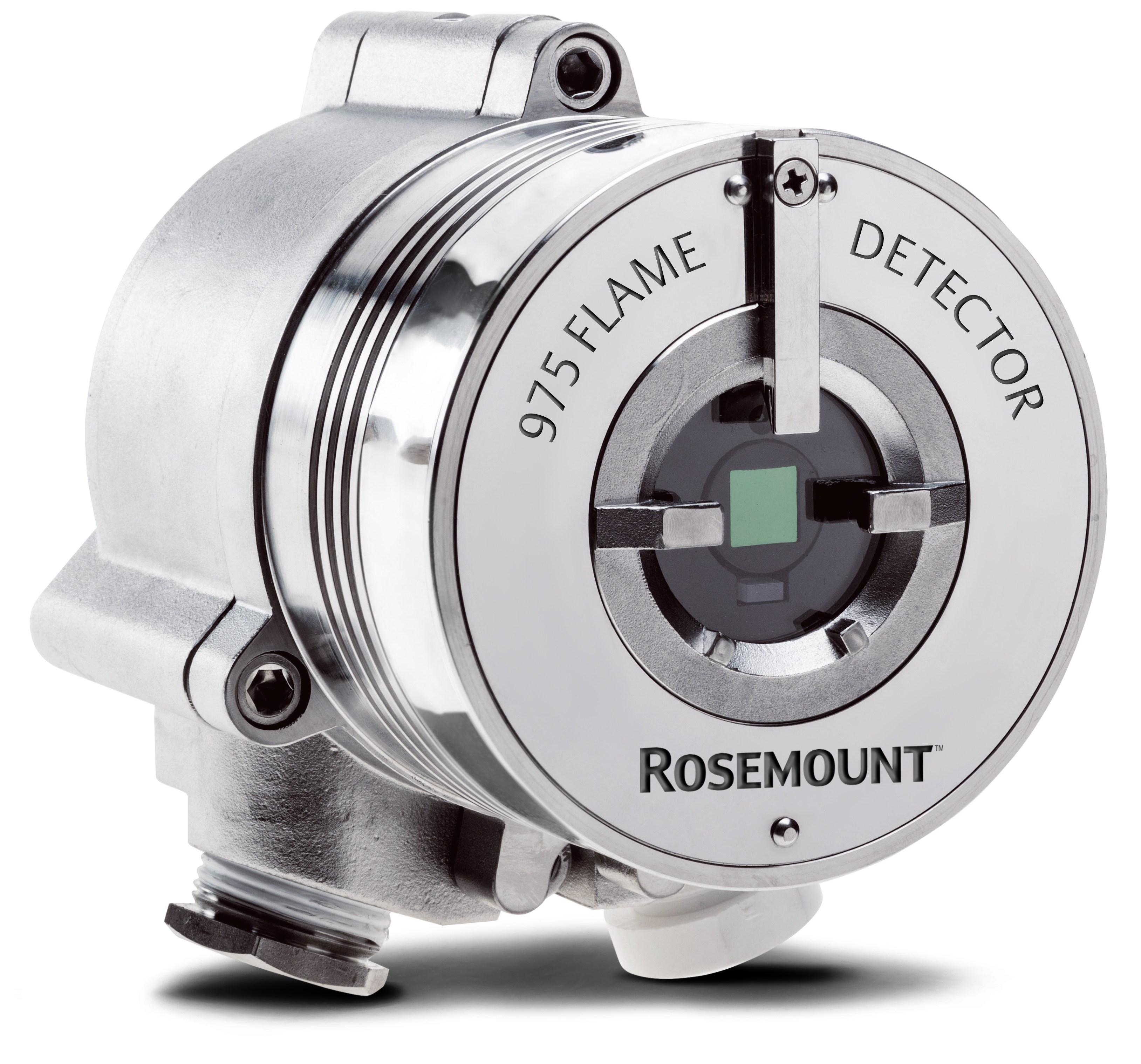

New Flame Detectors

Emerson, on July 18, announced the release of the Rosemount 975 flame detectors, a complete line of optical flame detectors designed to perform in the harshest environmental conditions and connect directly to alarm or automatic fire extinguishing systems.

“When you’re concerned with protecting lives and the future of your operations, you need an optimum solution for each facility and location,” said Lara Kauchak, vice president and general manager for flame and gas detection at Emerson. “We believe this comprehensive new line of flame detectors provides the reliability and functionality to meet all of our customers’ flame detection coverage needs.”

The new line incorporates a variety of flame detection technologies that will provide optimal coverage for a wide range of process industries, including upstream oil and gas installations, chemical plants, and refineries. Multi-spectrum infrared sensor technology detects hydrocarbon fuel and gas fires as well as “invisible” hydrogen fires with wide area coverage and strong false alarm immunity. Integrated ultraviolet and infrared sensor technology rapidly detects hydrocarbon-based fuel and gas fires, hydroxyl and hydrogen fires, as well as metal and inorganic fires with built-in false alarm immunity.

Built to be extremely durable and weather-resistant, the Rosemount 975 flame detectors feature heated windows for operation in harsh weather conditions, such as snow, ice, or condensation; broad operating temperature ranges from -67 to 185 degrees Fahrenheit (-55 to 85 degrees Celsius); and multiple output options for maximum flexibility and compatibility. The Rosemount 975 line is approved to Safety Integrity Level (SIL) 2 (TÜV). The detectors can even be tested in-field with a specially designed flame simulator at distances of up to 40 feet (12 meters) from the detector, eliminating the need for personnel to stand on scaffolding or supports to access the detector.

More information on the Rosemount 975 flame detectors can be found here: www.EmersonProcess.com/FlameGasDetection.

Deliquescent Desiccant 4UF

Van Air Systems has been the leader in deliquescent tablet production for over 70 years and offers several well-known deliquescent desiccant tablets. Van Air Systems would like to introduce a new high performance deliquescent desiccant known as 4UF/Gas Dry Ultimate. It was developed specifically to meet low dew point requirements when other desiccants or glycols are ineffective. Natural gas can be very difficult to process at low pressures, low flow rates, and/or low temperatures. For these unique applications, use GasDry Ultimate/4UF to dry natural gas to low water content.

Gas Dry Ultimate/4UF has advantages over other drying methods in many applications. It will provide moisture equilibrium down to 4 percent RH and will work at temperatures from below freezing to 80 degrees Fahrenheit. It is capable of providing up to 7 lbs moisture/MMSCF gas at temperatures below 32 degrees while operating at a very low 15 psig.

Van Air Systems new deliquescent desiccant GasDry Ultimate/4UF is now available—call 800-840-9906 or visit http://www.vanairsystems.com/products_desiccants/4uf.html.

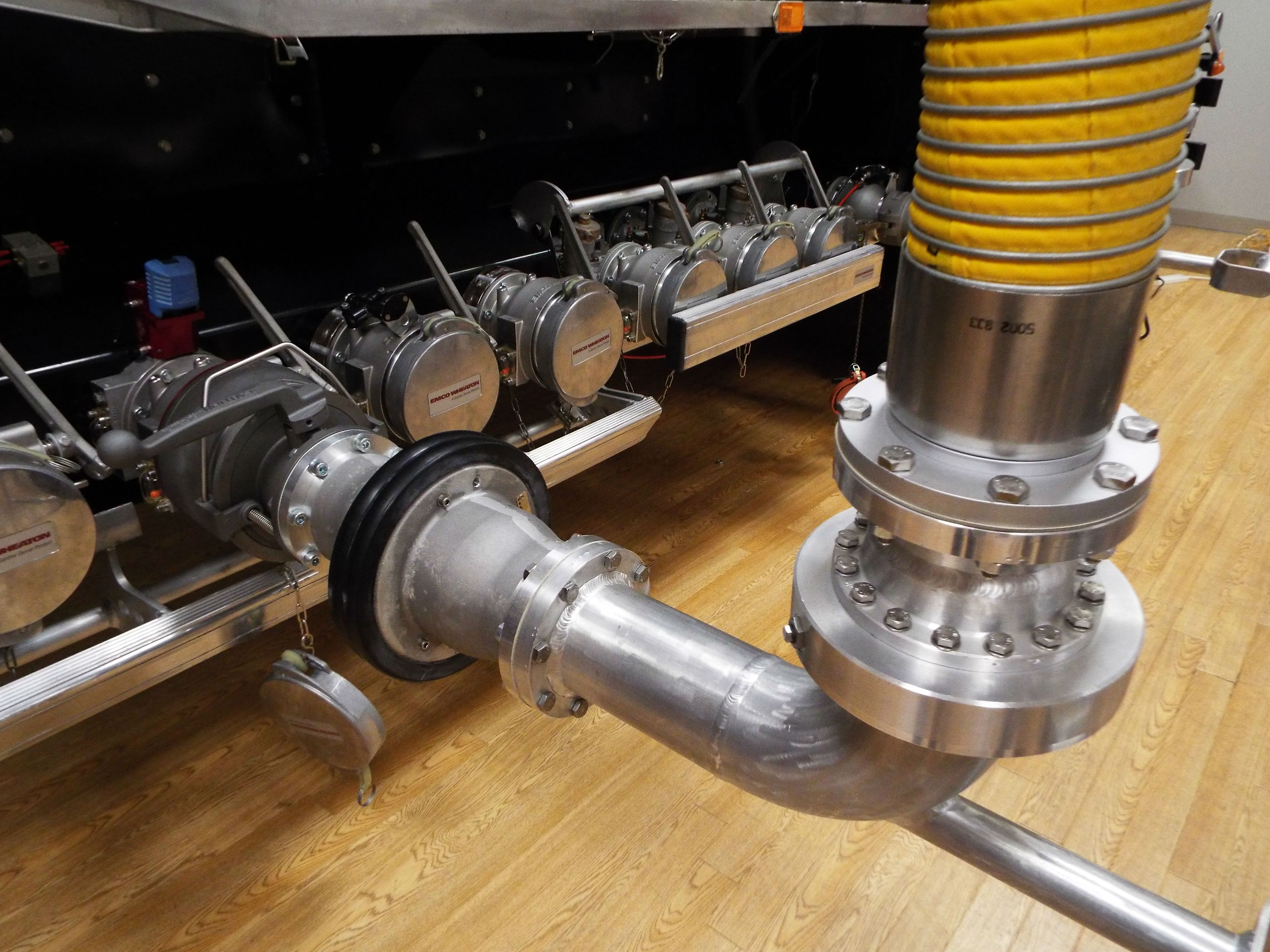

Break-Away Coupling

With operator safety paramount during loading and unloading of road tankers, Emco Wheaton’s new TODO Emergency Break-Away Coupling for bottom-loading applications will eliminate damages and risk of spillage while ensuring operators are protected against drive-away incidents.

The tried and tested TODO 4” Aluminium Break-Away has been specifically adapted for bottom loading arm applications with the addition of a TTMA flange. Not only can the device be applied on new loading arms, it also means the break-away can be retrofitted to bottom hose loading arms that currently incorporate this type of flange in their construction.

The addition of the flange and use of the break-away coupling gives operators peace of mind knowing that should a drive-away incident occur, the break-away will disconnect and minimize risk of product loss. Equally important, the break-away would take the force of the incident thereby protecting the API coupler and loading arm. By keeping the design concept simple, the break-away coupler can be re-set on site after an event with an easy to install kit so any downtime is reduced.

Emco Wheaton North American Product Manager for TODO Holly Damude said, “The consequences of drive-away incidents are very serious without break-away protection. Our new TODO TTMA break-away coupler removes the human error element when transferring dangerous fluids.”

The 4” Aluminium TODO TTMA Break-away consists of two identical halves joined together by a series of 3-mm break-pins, allowing the break-away to be configured to separate at a defined load. Should an excessive load be placed on the loading arm, the pins break and the break-away separates, automatically closing the internal valves. The break-away can then be reset onsite using an Emco Wheaton aftermarket kit.

This new variant of the break-away coupler is designed to operate reliably in hazardous conditions, ensuring that liquid is delivered without spillage or contamination, at all times protecting the driver and the environment.

Bluetooth Dataloggers for Corrosion Monitoring

<<<<< insert image 10NewAndNoteworthy_Cosasco >>>>>

Cosasco has released three new Bluetooth dataloggers for monitoring corrosion and erosion rates. The M-200, ER-200, and LPR-200 can be used in remote locations where direct online operation is not possible.

The ER-200 electrical resistance (ER) datalogger reads all ER standard and ER temperature probes. The M-200 Microcor ER datalogger reads all Microcor corrosion and erosion probes. The LPR-200 linear polarization resistance datalogger measures corrosion rate, pitting tendency and temperature in water systems.

All three dataloggers feature Bluetooth technology that allows users to download stored corrosion rate information collected from the dataloggers from up to 60 feet away with a handheld transfer unit (TU-500). Readings from the TU-500 are easily downloaded to a PC running Cosasco Data Offline corrosion management software, which then provides graphical displays of data for immediate identification of corrosion upsets. Multiple probes and additional corrosion related parameters can be reviewed simultaneously.

The dataloggers are certified intrinsically safe (IECEx/ ATEX/ CCSAUS) for operation in hazardous areas, and feature NEMA 4X IP66 rated enclosures for reliable operation.

For more information, visit www.cosasco.com.