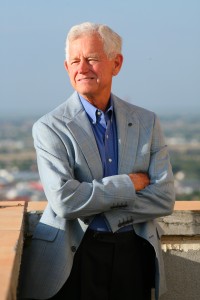

The word “Wolfberry” and the name “Jim Henry” will forever be linked in the petroleum history of the Permian Basin.

The story’s been told numerous times, and in various ways, but if there is a good “short version” of the tale, it’s in this capsule remark from Henry’s friend Jim White:

The story’s been told numerous times, and in various ways, but if there is a good “short version” of the tale, it’s in this capsule remark from Henry’s friend Jim White:

“He [Jim Henry] was the first one to develop the Wolfberry [formation]—it will make Midland a production center for many years to come,” said White, who is owner of JMW Petroleum and has known Jim Henry for more than 40 years. “He discovered it as a potential producer—it’s much like some of the shale formations you’ve heard about—it had been drilled through for several years and just had not been recognized as a potential economic performer. It’s not that he discovered a new reservoir. He discovered the potential of a reservoir.”

Henry himself, who is known for his generosity, would not go so far to claim the discovery for himself personally, preferring instead to spread credit around to his employees, past and present. But the fact is that Henry’s company was indeed the discoverer that White describes.

“It’s just been a boon to the West Texas economy and particularly the area around Midland,” White added. “You can see drilling rigs all around here that are the result of that economic discovery.”

The story of how that monumental play unfolded is rich in twists and revelations and even a sort of hide-and-seek game played out right in the very midst of the most carefully studied and heavily worked oil field in the country.

And even before that story began, there was an ironic twist that, in retrospect, seems almost to presage the plotline that would follow.

It was sometime back in the 1990s that a lease drilled by Arco—marking the last batch of some 300 wells drilled altogether by Arco in the Wolfcamp play, in the Midland Basin—would hold a clue to what might lie underneath. What’s ironic is that this lease—named Boltinghouse—came so late in Arco’s program, and yet was the first to show a significant uptick in potential. And yet when this lease showed promise finished, British Petroleum acquired Arco. And BP pulled out of the Wolfcamp for good. That Boltinghouse lease would catch the eye of Henry and his associates not long afterward.

In his own telling of the account, Henry starts somewhat earlier.

Back in 1969, Henry got into business for himself with Bob Landenberger, a geologist, and the two of them “started specializing in the Spraberry,” as Henry puts it, referring to another of the Midland Basin’s well known oil plays. In 1977 Henry would buy out his partner and form what would be known as Henry Petroleum. But under whatever company name, Henry and his associates “have been drilling in the Spraberry for over 40 years.”

And when a small independent specializes in one area, that company gets to know that area very well, Henry said.

Such a company “is in an enviable position to take and develop any rapidly growing trends—like the Wolfberry,” he said. “Because we understand what is going on. We understand the Basin. We understand particularly the Spraberry, and when we added the Wolfcamp to it, it became an economical sensation.”

That practice of working multiple formations became a Henry trademark, thought Henry credits Arco as being the pioneer in that field. Regardless, working multiple formations is now a standard for local producers.

So Henry and his team were already active in the Midland Basin when Arco was drilling its 300 wells.

“Arco in the 1990s had a farmout from Texaco and they drilled their [300] Wolfberry wells,” Henry said. “They started out just drilling Spraberry wells and they just started adding the Upper Wolfcamp and then they added the Middle Wolfcamp. They never added the Lower Wolfcamp. We added the Lower Wolfcamp. But they started fracking the wells. They developed frac techniques—huge frac techniques, ten times what the original frac techniques were.”

But Arco’s wells were only “marginally” economical. Except for the Boltinghouse lease. And when British Petroleum bought Arco out, BP did not continue drilling.

“We eventually started [there],” Henry said. “CMS, a Michigan utility, was operating here and Danny Campbell was head of CMS’s Midland office. He took the farmout from Arco. Well, he needed some help, because he didn’t have enough financing from CMS.”

That’s where Henry Petroleum stepped in. CMS farmed out 14 locations to Henry Petroleum.

“We had a three-fourths partner, and we had one-fourth,” said Henry. The partner was Pure Resources. Pure was bought out by Chevron. “And so we got to where we were working with Chevron.”

He grinned. “And we made Chevron several billion dollars.”

First, though, they had to simply make some kind of modest success in their new venture. The Boltinghouse lease would become a prototype for what Henry Petroleum would do.

They drilled the 14 locations, and the wells there were only “fair.” Henry’s geologists and engineers were charged with seeing what they could do to make it better. Part of their solution was to drill down through the Wolfcamp—all the way through the Wolfcamp, through even the lower Wolfcamp. Then the company hired Dennis Phelps to help them with their frac technique. It was Phelps who had helped Arco refine its own frac technique during their 300-well program. More of that Boltinghouse influence.

A Move to the Fringe

But perhaps a bigger step came when the company decided to move their efforts a little more to the fringe of the formation. Until that time, the drilling was concentrated in the middle of the Midland Basin—what would have been roughly the center of the floor of what had once been the Permian Sea. There, the oil-bearing rock was mostly shales or mudstones, possessing little permeability. The geologists reasoned that if they went to the regions away from the sedimentary-type center, they’d find oil-bearing formations with more gravelly or rocky components. Detritus, it is called, and it can be compared to the rubble-filled talus slopes that lie at the foot of canyon walls.

Henry pointed to a map—the same one reproduced here—and noted the positions of the Central Basin Platform and the Midland Basin. As the debris “falls off” the platform, the larger chunks lie nearest the fringe and the smaller ones distribute more toward the middle of the Basin. So “the facies change as you get down toward the middle, until you get down to shales and mudstones that don’t produce very good at all,” Henry said.

So they moved their operations from Midland County to Upton County, to what would be called the Sweetie Peck field, on that “fringe” of the Midland Basin. This was in 2003. They drilled a well called Caitlin 2801, “which is what you might call the discovery well of the Wolfberry field,” and they employed their new and refined frac techniques.

That well came in “very good,” producing about 150 barrels per day.

“So we said, ‘Well, this is a seems to be a good concept. Let’s step out a ways and see if it still works. So we went south about 20 miles.”

They drilled a well in what would be known as their Chickadee Field. And they learned that the Wolfberry formation in that region is a thicker payzone. Some 800 feet, as compared to the Sweetie Peck’s 400 feet of formation.

The Chickadee well came in strong, flowing more than 100 barrels a day.

“So we knew we had a significant discovery if we have two very economical wells 20 miles apart,” Henry said. “That meant it probably covered the whole area out there. So we started the program—that’s the Wolfberry program—and that’s when we made the deal with Pure where they owned ¾ of the acreage and we owned ¼. We kept on drilling like that. And the wells kept on coming in good. So we went out and made a serious effort at leasing up everything we could find in what appeared to be this trend.”

The Wolfberry name is a hybrid term that was coined by Henry Petroleum engineering manager Van Temple, who combined the names Wolfcamp and Spraberry.

The “Other Story”

“Now, there is an other story in this,” Henry said. And he commenced to tell about how Henry Resources kept their find under wraps.

“In 2003 we were drilling these new Wolfberry wells. And people couldn’t figure out what we were doing. We had been a Spraberry driller for 40 years. And we’d drill these [new] wells and they’d be put in Spraberry fields, because it is legal to commingle Spraberry and Wolfcamp. Initially, the wells would come in good. But we fracked them with [sufficient] water that you were producing a lot of water when you came back.”

Henry and team were orchestrating matters in such a way that the well results would initially look relatively unremarkable to anyone looking over their shoulders at how much oil their wells were flowing.

By putting more water in the ground, the initial production, which would include much of that water, would be greatly diluted. This meant that the oil production would seem modest.

They found they could take a well that ought to have a flow of 140 barrels of oil and make it look as though it produced only 40 barrels at its outset. Putting enough water in the formation would do that.

“So that kind of camouflaged things,” he said.

Unfortunately, the water content would taper off and the oil percentage would keep increasing until the true oil output was discernible some months after the well was completed.

But that’s where another phenomenon helped out.

Henry shared a graph that showed a well starting with 60 barrels of oil per day quickly spiking, some three months along, at 130 barrels of oil per day. But the graph also showed the flow then going into swift decline.

“Look how fast it dropped off,” he said. [See accompanying chart.] “People would see how, after a year or so of us producing, it had come down so much. And they’d say, ‘That’s not economical.’

What these observers did not realize is that the decline flattened out and ran relatively steady from a certain point onward. The curve acquired the proverbial “long tail.”

“So that was the second thing that camouflaged it. They didn’t think we were doing any good. It was up to 130 barrels per day in the third month, and then it drops off fast. So it looked just like a flash in the pan. Which the Wolfcamp had been for the last 50 years.”

And why didn’t people see that the dropoff flattened out?

Henry points to the graph again. “That’s out here about two or three years.” The observers weren’t watching that long.

Why did the production level out 2-3 years into its lifespan?

“That’s just the nature of the Wolfberry—particularly the nature of the Spraberry,” says the guy with 40 years’ experience in the Spraberry. (And these being multiple plays, one play’s characteristics can camouflage another’s, apparently.)

Altogether, in its wild ride in the 2003-2008 era, Henry Petroleum leased up 330,000 acres. By 2005, other operators were finally catching on.

By this point, the most colorful era in Henry Petroleum’s history was nearing its end, though the company’s breakthroughs would continue—do continue—to transform the region. But the competition was coming, and the bidding for leases would drive prices higher and higher. The best days would be behind.

Henry Petroleum sold out to Concho Resources in 2008, transferring over to them their 330,000 acres that included some 1,000 well completions.

Now called Henry Resources, the company is still drilling. They went from 40 employees and three rigs before the Wolfberry discovery to more than 100 employees and ten rigs at the time of the sale, to about 40 employees and three rigs at present.

“We’re still drilling wells,” Henry said. “ We’ve gone further north and we’re right next to Midland now, where we’re drilling our wells. We have about 100 more locations to drill.”

The Big Picture

“What’s interesting is that of the 330,000 acres, only about 110,000 acres were economical [at the time of the sale]. Some 220,000 were ‘not economical.’ But part of that acreage was over in Glasscock County, in the eastern part of the Midland Basin, and since we sold out to Concho the people over there on the eastern part have figured out how to make it economical. They have added a lot more formations and it is going great guns over there.

“That’s what happens lots of times, when you start in on a play like this: you figure out how to do better,” he added. “We figured out how to do better at the start of the Wolfberry, but then we didn’t figure out the Glasscock County stuff. The people who came in after us figured out .

Referring to yet more maps [not shown], Henry pointed out that, in 1997, 316 Wolfcamp producers had been drilled. Between 1997 and 2002, 554 Wolfberry wells were drilled. But between 2003 and 2011, 3,000 Wolfberry wells were drilled.

He points to some areas nearby that await production, and he says, “If it all is drilled up in here and if you include some of the Glasscock County production, you come with a total ultimate recovery of over three billion barrels of oil.

“Three billion barrels. Which, according to the Bureau of Economic Geology, is the largest discovery in the Permian Basin in the last 50 years.”

Recently, news accounts reported a find in the North Sea that is expected to produce about a billion barrels of oil. This discovery is touted as “one of the largest fields ever discovered.”

But that field (near Norway) is only a third as big as the Wolfberry.

“And ours is here in the United States and it is in a field that has been drilled around and through for 70, 80 years,” he said.