The Journal of Petroleum Technology ran an excellent article on proppant flowback, focusing on how much sand comes back after frac’ing.

The graphic at right is from the Society of Petroleum Engineers’ online magazine, JPT (Journal of Petroleum Technology), where an article was recently published discussing how much frac sand (a whole lot, it turns out) is actually now being flowed back in the Delaware Basin. (Find the article here: https://tinyurl.com/bdpem99a). From an operational standpoint it is truly amazing they can stuff all that frac sand into those Wolfcamp and Bone Springs wells in the first place. Even more amazing is how much of it now gets crapped back out during flowback. I haven’t a clue how these enormous production costs are handled in Non-GAAP accounting and ensuing well economics… [But] I find the entire article enlightening…especially if you are reading between the lines. As the author writes, “It is the sign of the times.”

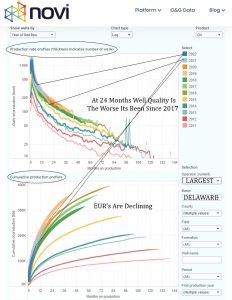

I’ve shown repeatedly, using actual realized production data filed by horizontal operators with the Texas Railroad Commission, how well productivity by almost any definition is falling in the Delaware Basin and has been since 2017. In spite of a gradual move to longer laterals, from the 6-7K feet type to the 10-11K feet type, initial potentials of wells may be increasing ever so slightly but then ensuing decline rates after 18-24 months are steeper. And though it is too early to know for sure, EUR’s will not be greater. In fact they could prove to be less.

As I have also often written, well productivity is not necessarily a function of rock, but is more a function of how flowback is managed by the operator. It is a function of choke management and how important it is to an operator to get as much money from the well initially as possible. Far too many analysts and internet students of tight oil believe all wells are the same, like coke cans dropped out of vending machine. They are not. At least one top E&P in the Permian is renowned for gutting its wells initially for cash flow purposes. Read this JPT article and then you’ll understand a little better.

The data that informs these graphs is realized production data from operators that was filed with the Texas Railroad Commission. Novi, the name atop these charts, is simply a data company that deals in dashboards and chart-plotting software.

I read this article with operational interest as to how that frac sand is handled on the surface during flowback, but then it occurs to me, holy sh**, these guys are flowing these wells back so hard, for up front cash flow, they don’t give a rat’s ass about EUR’s. What they are doing has nothing to with long term resource management. They’re just after the bucks. Frac sand once put in place is supposed to STAY in place, keep nano-fractures propped open, and help increase fluid conductivity to the well bore for maximum drainage of the SRV (Stimulated Reservoir Volume, i.e., the shale “cylinder” that is stimulated around the HZ lateral). A lot of that proppant is now, it seems, getting puked back out of the lateral leaving those nano-fractures to close.

For example, as the JPT article indicated, flowback can produce 5,000 pounds of frac sand per hour! Sometimes 30-35 percent of total proppant that gets loaded… gets unloaded.

Who cares? Someone interested in how much Permian Basin oil there is left to recover should care. Some dumb SOB like me who is worried about the long term energy security of his country should care. Because this sort of sh** means to me, plain as day, that tight oil companies are plenty fine with 8 percent of OOIP recovery rates. And as they pressure deplete these SRV’s there is a bunch of valuable American oil resources being left behind, now almost totally immobile, stranded forever.

I believe this amazing resource is being totally mis-managed on so many levels by operators, mineral owners (drilling commitments), marketing outlets, regulators on the State level and in Washington. It’s a testament to how greed is totally ruining a good thing for our country. 100% on that.

Mike Shellman, a lifelong oilman and CEO of MCA Petroleum, operates 53 wells and still drills wells every year, using his own geology, with his own money. A published writer and a published photographer, Shellman belongs to the Society of Petroleum Engineers, the American Association of Petroleum Geologists, the South Texas Geological Society, and the Produced Water Society. He is a proud member of the Association For the Study of Peak Oil. He is passionate about his industry, its history, and the future hydrocarbons will play in the world our children will live in. He maintains a popular blog that can be found at OilyStuffBlog.com.