Whether you call it “seismic” or “geophysical,” this industry-within-an-industry keeps broadening its frontiers.

On a hot day in June 1921 the first successful test of the reflection seismograph was completed north of Oklahoma City. “Here we are in 2013, less than a hundred years later, and a lot of exciting things are happening,” said Kevin Werth, chief geophysicist for Dawson Geophysical in Oklahoma City.

The geophysical business, or seismic, has “exploded” in recent years as exploration and production companies expand into unconventional plays across the country. The business continually changes with new technology that allows better imaging, more accurate interpretation of the data, less equipment, fewer man hours, and a reduced impact on the environment.

Dawson Geophysical, headquartered in Midland, has been “shooting” for 60 years and expanding slowly across the United States with a recent move into Canada. On the other end of the spectrum is Houston-based Global Geophysics. It was started in 2005 as a data service focusing on land and shallow marine plays, according to Larry M. Scott, vice president of Microseismic, Global Microseismic Services. The company employing 800 people now works throughout the world, including Algeria, Argentina, Brazil, India, Oman, Peru, Poland, Mexico, and Russia.

“Seismic isn’t a light undertaking,” Werth said. “It’s a very complex business of looking for oil and gas and requires a massive amount of equipment.”

Werth condensed all the seismic technological advances into one word: wireless. That may help to reduce the amount of equipment required by the industry.

“For the seismic industry, the biggest technological advance is wireless seismic recording. We are getting rid of the cables that have burdened our crews,” Werth said. “The exciting thing is it changes the way we record our jobs, the way we are doing our 3-D sweep for our clients and the potential to see more detail in the subsurface. It also increases our production time. We acquire 3-D surveys faster. This helps us cut back on time spent on our jobs, fewer man hours involved.”

Scott explained that his company has developed recording devices called Autoseis HDR-1 autonomous nodal recording units. According to the company’s information, these units have no interconnecting cables or complex radio links between nodes and gives “true 32-bit seismic data. This autonomous nodal recording technology represents a clear breakthrough in terms of crew productivity, data quality, and reduced environmental impact.”

“We were involved in high end data acquisition projects that had large channel counts that were hard to process. We developed our own recording device” which involved developing the microseismic department for Global Geophysical Services. With the technology, their crews and front-end people are getting into the fields earlier, he noted.

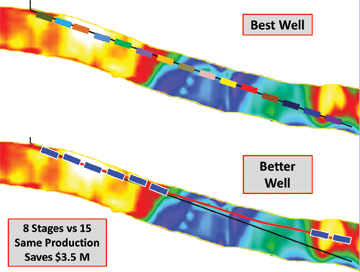

“On the interpretation side, we have a consulting model in which we are working with exploration and production companies to help with the drilling and completion phase,” Scott said. “In these shale plays, for example, we know there is a lot of oil down there—but what is the least costly way to produce it? We take all the data and help the E&P companies execute better decisions in these plays.”

This Autoseis technology is “one of the key enabling technologies for both Ultra RG3D as well as high fidelity microseismic monitoring,” he added. “It is helping us set records in terms of crew productivity.”

With RG3D, Global Geophysical is focusing on very dense spatial sampling; recording long offsets which allow the company to obtain good structural images; and obtaining rich-azimuth recording to allow illumination and analysis of the subsurface more than 360 degrees. The latter process allows the staff to understand stress field magnitude and orientation as well as the presence and orientation of fractures that potentially constitute important permeability pathways in the reservoir, according to information submitted by Global Geophysical.

“Instead of illuminating a reservoir in a single direction, it’s as though we move a flashlight around it 360 degrees,” Scott explained. “We can see the potential density of fractures.”

“Instead of illuminating a reservoir in a single direction, it’s as though we move a flashlight around it 360 degrees,” Scott explained. “We can see the potential density of fractures.”

Global advertises its fleet of 90 new ION vibrators and its 150,000 channels of recording gear.

Dawson Geophysical announced in December it was purchasing 12,000 channels of Geospace single channel GSX cable-less recording equipment. This will replace an RSR recording system on one of the company’s existing data acquisition crews. This will give Dawson 73,000 channels of GSR and GSX equipment and 179,000 channels total. The company also is adding 10 INOVA AHV IV 364 vibrator energy source units, putting the total number of vibrator energy source units up to 179.

“Dawson is making a big financial commitment by buying this leading technology,” Werth said. “This will allow seven of our 14 crews in the field to be cable-less. We’ve been moving to wireless in the past two years.”

Cables, he noted, are costly to any company. “There’s this great phenomenon in the field that cattle love cables. The men who handle them have sweat on their hands and the cattle like to lick that salt. They will bite the cables.” So do rodents. This means crews are constantly repairing or replacing cables. “The wireless system will reduce downtime needed to fix systems,” Werth said. “We can spend $100,000 a month in cable repair. These cable-less systems are a great benefit.”

The wireless system also will prove beneficial in metropolitan areas. “We can do a great job without having cable stretching across a sidewalk,” he noted.

Wireless leaves less of an environmental footprint and that factor is important to seismic companies. “It’s safer for employees and there is much less impact on the environment. That is important to Dawson,” Werth said.

Geospace was the manufacturer selected by Dawson Geophysical after the company tested several brands. “This one was a good fit for Dawson,” said the Oklahoma City geophysicist.

The INOVA vibrator “is the newest vintage of vibrating buggies for the field” and will replace some older technology at the company. “We continue to keep our inventory up,” he added.

Both companies are working in major plays across the United States. Scott said Global Geophysical is working in the Eagle Ford, Bakken, Niobrara, Utica, and Marcellus. “We’re in the majority of unconventional plays.” They also are involved in an RG3D University Lands multi-client project in Upton, Reagan, and Crockett counties. In addition to the ones listed above, with the exception of the Utica, Dawson Geophysical is working in the Mississippian Lime, Permian, and Avalon.

“The Permian is interesting to us,” Scott noted. “It has much tighter formations that are not classic shale. They’re very limey shales. There is a whole range of plays that can benefit from these advanced technologies.”

Scott talked about the Tomographic Fracture Imaging (TFI) that Global Geophysics is utilizing. “It directly images both hydraulic and natural fractures as complex surfaces and networks,” a company report noted. “These are direct images of cumulative seismic activity over time intervals. TFI also can image natural seismic emissions during quiet-time recording on 3-D reflection grids and these can be used for monitoring production or steam, water, or CO2 floods.”

He pointed out another advantage to the improved technology: “We’re getting the engineers and geophysicists to talk to each other. Engineering and geophysics are different cultures, but the gap is closing out of necessity.”

Dawson Geophysical Werth’s pointed out a new technology that is being looked at closely: multi-component shear-wave acquisition. “It’s really an old technology that hasn’t been exploited. We’re about to start doing some work with these multi-component geophones, and we’re beginning to get a grasp on it. It’s shear-wave vibracize with the geophones.”

Dawson Geophysical has opened a Calgary office and Werth said the company plans to start seismic work in that area this winter. “To do 3-D seismic surveys in Canada, the shooting season is in the winter. Tundras are fragile and have to remain frozen. We will be working in the oil sands up there. We’re taking the wireless system because it will leave less of a surface footprint. That is a concern in Canada.”

The Calgary office marks the first step that Dawson has taken outside the continental United States. “We’re very pleased with the early results we’ve had since opening the office,” Werth said of the number of clients signing up for projects with them.

As for Global Geophysical, its growth exploded number-wise in the first few years as it added crews, services, and employees. “Most of our growth over the past three years has been vertical growth into full-service engineering and geophysical services,” Scott said. “This is a very dynamic time for the company.”

Werth opened the Oklahoma City office for Dawson Geophysical 10 years ago as a one-man operation. Today, the office boasts 13 employees.

“There are huge changes in the seismic field,” he said. “Cable-less is monumental for us, plus the additional imaging capability. We are continually looking for new technology. These cable-less systems afford us the ability to look at other technology that we haven’t been able to before.

“Seismic has been around since 1921 and here we are in 2013. A lot of really exciting things are happening in seismic. A year from now, we could be talking about more new technology,” Werth said.